RICHI MACHINERY TURNKEY SERVICE

Henan RICHI Machinery Co., Ltd. was established in 1995, has been committed to providing customers with turnkey services of feed processing machinery and engineering, biomass pellet production line, steel structure engineering, silo, automation control, including project consulting, solution design, equipment manufacturing and testing, installation and commissioning, technical guidance and maintenance services.

500+

Device Models

500+

Device Models

500+

Device Models

500+

Device Models

How to Choose the Right Machine

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process

1

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

2

3

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

4

5

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

Project Consulting

RICHI Machinery can provide professional consulting services, including assisting customers to analyze the local pellet market, the current situation of the pellet machinery industry, the feasible solutions for animal feed or biomass pellet production, the technical problems in the production of feed pellets, floating fish extruded pellets and wood pellets, and how to choose the equipment model on the pellet production line.

6

How to Choose the Right Machine

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process

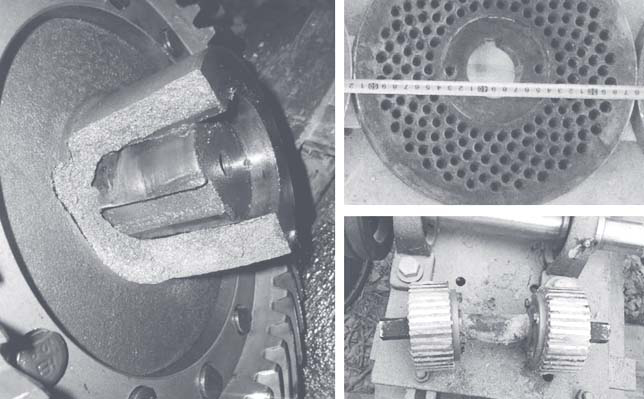

PELLET MILL PROBLEMS

in global mine development projects

Almost all exceeds the investment budget;

A

Almost all exceeds the investment budget;

B

Almost all exceeds the investment budget;

C

A

Design & Research

B

Equipment Procurement

C

Construction & Installation

Advantages

Lead to over investment, project delay, and the technological transformation since put into production.

Practical Solution Design

Understand customer’s needs, such as capacity, final pellet size and quality, raw materials;

Consider our customer’s budget, site and realistic conditions;

Professional technical and designer team to customize the feasible solution of the customer.

Quality Pellet Equipment

Cooperation with Siemens, SKF, Schneider, NSK, FAG, ABB and other international brands.

Large CNC cutting machine, automatic arc-submerging welder, dynamic balance detector, sand blasting rust and paint production line and other advanced process equipment.

Quality machine material selection and excellent design details;

The whole process of equipment production will be in constant communication with the customer to ensure quality and schedule.

Ensure Well-Running

Our equipment installers come from our own factories, and any problems can be solved in a timely manner.

How to Choose the Right Machine

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process

Brief

Henan RICHI Machinery Co., Ltd. has its own standard factory, a group of lean production first-line employees, a high quality professional technical team and its own sales team. As a turnkey service provider, RICHI Machinery is also a manufacturer integrating feed machinery complete engineering, biomass pellet complete engineering, steel silo engineering and automation control R & D and manufacturing, engineering design and installation. Our products have been exported to Europe, the Middle East, Asia, Southeast Asia, Africa and other 127 countries and regions, more than 2,000 customers.

RICHI can provide customers with chicken, duck and other poultry feed pellet production lines, cattle, sheep and other ruminant feed production lines, composite line for different final pellet products, wood pellet production line, biomass pellet production line, etc. We can also provide customers with different capacity of pellet production lines. Each pellet production line has multiple processes, and the conveying equipment between each process and process is not the same. If you want to set up your own pellet production line, please contact us.

Animal feed or biomass pellet production line turnkey service global provider.

Why Choose Richi Turnkey Service?

As the leading manufacturer, supplier and exporter of feed machinery and biomass production lines in China, RICHI Machinery’s turnkey service has been highly recognized by customers. After nearly 30 years of development, RICHI’s projects have spread all over the world and accumulated rich experience. Also, many customers like our unique solution designs, which are very customer-friendly. In addition, because of the high quality of our equipment, we have many repeat customers, and we are very happy to reach such a long-term cooperation.

01

Rich experience in domestic and foreign projects

02

Rich experience in domestic and foreign projects

As a proposer and practitioner in mine EPCM+O service, Xinhai has served nearly 2,000 mines and completed over 500 EPCM+O projects in more than 100 countries and regions around the world. Xinhai installation and commissioning department has carried out installation and commissioning work at home and abroad all year round. It has more than ten years of practical experience and establishes a scientific and efficient assessment system so that each EPCM+O project can be completed according to standardization, process and intelligence.

01

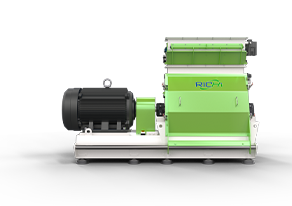

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

02

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

03

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

04

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

05

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat,

03

Rich experience in domestic and foreign projects

RICHI Machinery has European CE certification, German TüV certification, Swiss SGS certification, Russian RTN certification, French BV certification, ISO9001 quality system certification, with a sound international trade system. RICHI also has obtained nearly 20 patents.

How to Choose the Right Machine

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Wood pellet plant project

Qualification Certification

Inquire for More Turnkey Service Products, Tell Us about Your Situations:

- What Kind of your raw materials? Grain, biomass or organic fertilizer?

- What kind of pellets do you want to produce? Animal feed, grass-containing feed pellets, burning pellets or extruded pellets?

- How much capacity do you want? You can choose 1-100T/H.

- Tell us your budget and plant size.