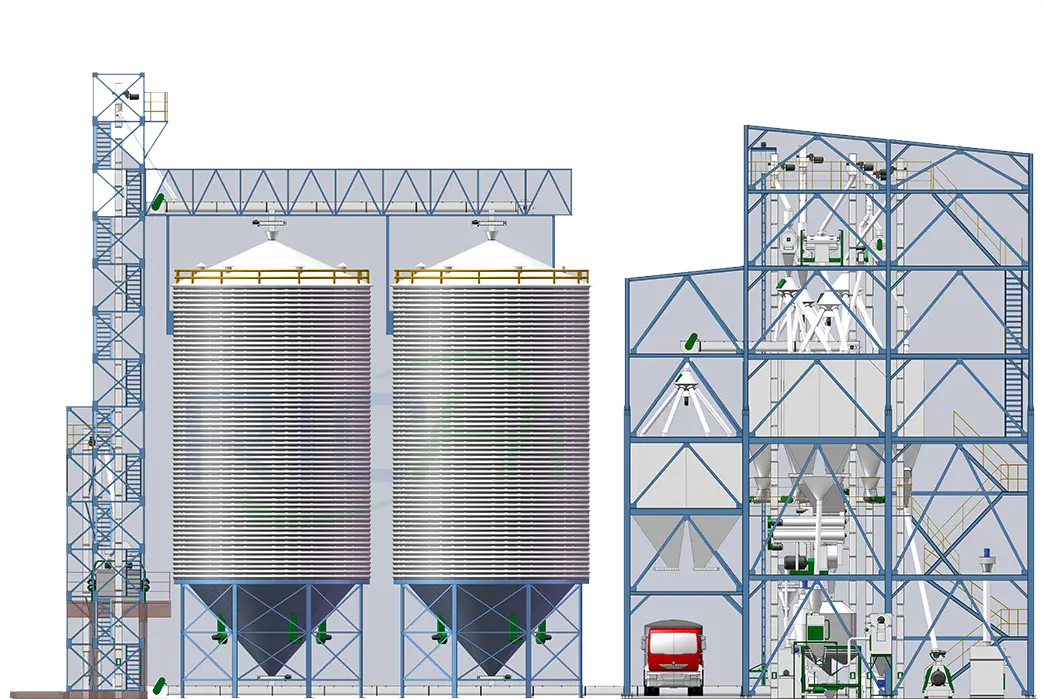

Feed production line

Henan RICHI Machinery Co., Ltd. was founded in 1995, has its own factory, is a feed machinery equipment, biomass pellet equipment manufacturers and suppliers.

Product Introduction

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines.

lt has a unique design that allows precise control over the density of the final feed, making it possible to produceeither floating or sinking feed as needed, At the same time, operators can aciust the process parameters to controlthe texture of the feed, such as its ability to absorb oil during later coating processes.

As a professional feed machinery manufacturer, RiCHl offers dry fish feed extruders mainly for producing aquatic feed pellets with diameters ranging from 0.5 to 8 mm in various shapes and lengths. They can also be used to produce pet or poultry feed pellets up to 50 mm in diameter.

30 Years Of IndustryExperience

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Complete After-Sales Service

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Built Around Your Needs

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Feed Pellet Machine For Sale

Fish feed processing line can process floating fish feed, pet feed, and some high-endextruded feed for livestock and poultry. it can also be upgraded to a combined feedproduction line, process shrimp feed, crab feed, eel feed, pet food livestock andpoultry feed, premix and other products at the same time.

It is usually invested and built by fish feed factories, aquatic feed factories, petfeed factories, compound feed factories, fish farms, aquatic processing plants.etc. Of course, there are also many investors from different industries who are veryoptimistic about the prospects of fish feed processing, so they enter the aquaticfeed processing industry.

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

Brief Introduction of

Shrimp Feed Machine

Shrimp feed factories usually use a complete shrimp feed production line when producing shrimp feed. Because using a complete shrimp feed production line to produce shrimp feed can significantly improve the production efficiency and quality of shrimp feed.

Relying on rich experience, Ruiqi has carefully designed a complete set of shrimp feed production lines for shrimp feed factories and created a turnkey shrimp feed production project.

Receiving and processing of raw materials1

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials2

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials3

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials4

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials5

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials6

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials7

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials8

Receive raw materials according to the feed formula and remove impurities and store them

Receiving and processing of raw materials9

Receive raw materials according to the feed formula and remove impurities and store them

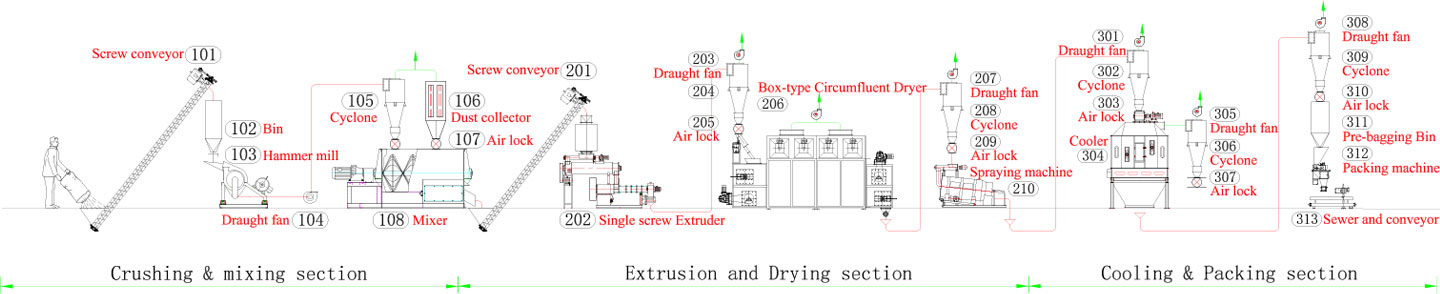

Feed Pellet Production Line Working Process For Small Capacity

‘ezoisno ol sn oluo eal indinohup jo alu uononpold p pling ol peau eu ehpy noh lflul buxpw! elad peelipwlup uh7! p s11 ‘eouelelel noh jol ubiseo uooam pu alu uogpnpold pee, indno jolso oapin pup poyo moy au s fumoloy aul “spuup sno!pn oj agqpins au uopnpold aled pal, aadw0o p joubsep au! apold uno am ‘srawoisryo speau oypadseu . 6uplooy weshs bul6oyond puo ‘waishs buoo waisils buzegad “weaishs bukw ‘sulegshs buusnl5 pyepu mp!sapnpu! Aupu a uopnpold gaed pee! ul

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

RICHI VIDEO

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions

The Main Equipment Of The Feed Pellet Production Line

We can design feed pellet lines of various production capacity, the following is the flow chart and video of large output feed production line that we can design for your reference. It is a 8-12t/h animal feed production line, if you have any pelletizing requirements, welcome to contact us to provide you with pelletizing solutions.

Customization

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Customization

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Customization

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Customization

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Easy to maintain and maintain

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Customization

This section mainly expr

esses that the pro This section mainly expresses that the pro This section mainly expr

esses that the pro

Customized design

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

All of Ruiqi’s floating fish feed production lines are custom designed. Tailored professional floating fish feed production plants for customers based on different raw materials, limitations in site size and height, requirements for automation level, and production capacity.

0.5 ton floating fish feed production line

Type of Feed Produced: Floating Feed

Process flow: Crushing system – Mixing system – Extrusion system – Drying system – Cooling system – Packaging system

Main equipment used: crusher, mixer, single screw extruder, oven, screening equipment, cooling machine, packaging equipment

Why Choose RICH?

A Professional and Leading Manufacturer

RiCHl Machinery has been dedicated to extrusion technology for nearly 30 years, We are committed to providingglobal customers with efficient and reliable fish feed extruders and complete solutions, We focus on the researchand innovation of feed production equipment, continuously improving performance to help customers increaseproduction efficiency and product quality.

Our fish feed extruders are not only suitable for various types of aquafeedprocessing, but also widely used in pet food, poultry and livestock feed,and grain-based food production, meeting diverse manufacturing needs.

With an experienced technical team and comprehensive service support, RICHlbuilds intelligent and efficient feed processing systems for customers around theworld. We are your trusted long-term partner. We offer:

Consulting and Engineering Planning

We provide full factory construction servicesfrom raw material input to finished productpackaging. You just need to “turn the key” andstart production. The system is efficient andstable, helping you improve efficiency, reducecosts, and save time and effort.

Consulting and Engineering Planning

We provide full factory construction servicesfrom raw material input to finished productpackaging. You just need to “turn the key” andstart production. The system is efficient andstable, helping you improve efficiency, reducecosts, and save time and effort.

Consulting and Engineering Planning

We provide full factory construction servicesfrom raw material input to finished productpackaging. You just need to “turn the key” andstart production. The system is efficient andstable, helping you improve efficiency, reducecosts, and save time and effort.

Frequently Asked Questions

We are a professional manufacturer of fish feed extruders and offer a variety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder. if you need a machine with a different capacity, please let us know your requirements, and we will customize a solution for you.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.