CUSTOM TURNKEY AOUATIC

FEED MILL SOLUTIONS

From project design to equipment installation,

we provide complete and directly operational feed mill solutions for fish, shrimp, and pet feed plants.

INTRODUCTION TO

SHRIMP FEED PELLET LINE

As gilobaleading shimp fed making machine manufacturer, we have been deply involved in the field of shrimp feed pellet production for neary 30 year. We canprovide you with a ful set of shrmp feed making machine, shrimp feed pelet line turkey proiects, and customized solutions for shrimp fed peet mi. 0ur experencand expertise enables us to provide you with comprehensie advce and hasle-free serice througout your shrimp feed production proces This production line excelsin eficient oeration, stable perormance.and fexible confcuratlon. No mater what kind ofshrimp feed you want o produce, it can be fexlbly adlusted according to

the formula and market demand.

Whether you’re bulding a new feed millor upgrading an existing line,RicH!can provide you with a cost-efective complete production ine solution, making your production smoother, costs more controllable, and profits more stable.

Application

Litopenaeus vannamei. Penaeu smonodon, Litopenaeus setiferus.Farfantepenaeus aztecus. red tailshrimp, Macrobrachium rosenbergi..

Application

Litopenaeus vannamei. Penaeu smonodon, Litopenaeus setiferus.Farfantepenaeus aztecus. red tailshrimp, Macrobrachium rosenbergi..

0.5-40 T/H

Capacity Range

Application

Litopenaeus vannamei. Penaeu smonodon, Litopenaeus setiferus.Farfantepenaeus aztecus. red tailshrimp, Macrobrachium rosenbergi..

SHRIMP FEED PRODUCTION PROCESS

Shrimp feed pellet production mainly involves two processes: pelleting and extrusion.Pelletizina is a mature and widely used process: however, with the refineddevelopment of shrimp farming, extrusion has gained popularity due to its high pellet density and good stability.complete production lines. Regardless of which process used. weensure stable and effcient production performance.

RiCHl has years of experience in feed peleting and extrusion technology, providing customers with shrimp feed manufactuing solutions ranging from single machines to

SHRIMP

FEED PRODUCTION PROCESS

SHRIMP FEED PRODUCTION PROCESS

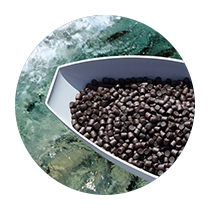

Shrimp feed pelet production mainlyinvolves two processes; pelleting and extrusion. Pelletizing is a mature and widely ued proces; however, with the retined development of shrimp farming, extrusion has gained popularity due to its high pellet density and good stability.

RICHl has years ofexperience in feed peleting and extrusion technolgy, providing customers with shrimp fed manufacturing solutions ranging from single machines to complete production lines, Regardless of which process used, we ensure stable and eficient production performance.

Shrimp Feed Pellet Machine For Sale

Particle state: Pelletized shrimp feedTarget Shrimp Species: Adult white shrimp, freshwater shrimp. giantfres hwater prawn

This equipment features a three-layer regulator and produces pelleted shrimp feed through ringdie compression, it offers lower energy consumption (electricity, steam), suitable for large-scale.cost-effective adult shrimp farming scenarios, especially for small and medium-sized farmerswith feed budgets.

Shrimp Feed Pellet Machine For Sale

Particle state: Pelletized shrimp feedTarget Shrimp Species: Adult white shrimp, freshwater shrimp. giantfres hwater prawn

This equipment features a three-layer regulator and produces pelleted shrimp feed through ringdie compression, it offers lower energy consumption (electricity, steam), suitable for large-scale.cost-effective

CHARACTERISTICS

OF SHRIMP FEED PELLET LINE

This shrimp feed pellet production line is specifically designed for shrimp farming, From process confiquration to equipment structureit fully considers the requirements of shrimp feed for stability, palatability. and nutrient retention.Utilizing advanced pelleting and extrusion technology, this complete system ensures that shrimp feed pellets maintain their ideal form

and balanced nutrition in water, making it the perfect production solution for professional shrimp feed manufacturers

Customized Design

The shrimp feed pellet millcan be customized according to the size ofthe plant and specific needs.

Customized Design

The entire process of the shrimp feedpellet line is modular in design, and theproduction sections can be increased ordecreased according to the raw materialsused and special needs

Customized Design

The shrimp feed pellet millcan be customized according to the size ofthe plant and specific needs.

Customized Design

The shrimp feed pellet millcan be customized according to the size ofthe plant and specific needs.

Customized Design

The entire process of the shrimp feedpellet line is modular in design, and theproduction sections can be increased ordecreased according to the raw materialsused and special needs

Customized Design

The shrimp feed pellet millcan be customized according to the size ofthe plant and specific needs.

SHRIMP FEED PRODUCTION PROCESS

shrimp feed pelet production mainly invowes two processes: peleting and extrusion, Pelletizing is a mature and widely used process: however, with the refined development of shrimp farming, extrusion has gained popularity due to its high pellet density and good stability.

RiCHl has years of experience in feed peleting and extrusion technolgy. providing customers with shrimp feed manufacturing solutions anging from single machines to complete production lines. Regardless of which process used, we ensure stable and efficient production performance

OUR BUSINESS, NEVER JUST EQUIPMENT

We are a professional manufacturer of fish feed extruders and offer a variety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder. if you need a machine witha different capacity, please let us know your requirements, and we will customize a solution for you.

Feed Machinery and Engineering

all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.

Feed Machinery and Engineering

all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.

Feed Machinery and Engineering

all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.

Feed Machinery and Engineering

all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.all our products have lS09001:2008, CE, and CU-TR certifications.

all our products have lS09001:2008, CE, and CU-TR certifications.

We are a professional manufacturer of fish feed extruders and offer a variety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder. if you need a machine witha different capacity, please let us know your requirements, and we will customize a solution for you.

A fish feed production line is basically a set of machinery and equipment that automatically makesfeed for fish and other aquatic creatures like shrimp and crabs. it turns fish meal, soybean meal,flour and other raw materials into high-quality, nutritionally balanced fish feed through

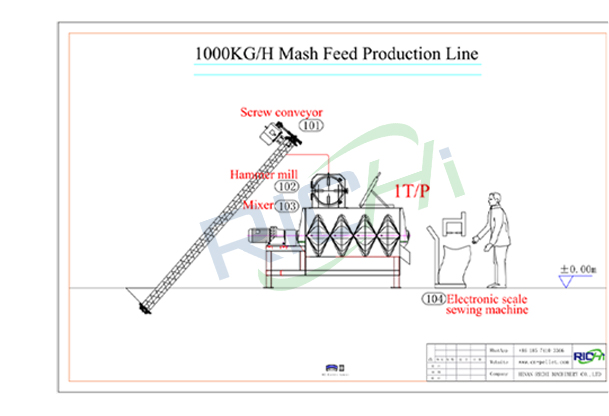

CUSTOMIZED SHRIMP FEED PELLET LINE DESICN

There is no “best” production line, only the “‘most suitable solution for you. Customized solutions can help iferent customers meet their unique business needs, improvelficiency, and reduce costs. l of RlcHrs shrimp feed production ines are custom designed. Tailored professionalshimp feed production plants for customers based ondifferent raw materials, limitations in site size and height, requirements for automation level, and production capacity

How to choose a suitable shrimp feed production line?

When choosing a shrimp feed production line, you should consider several key factors to ensure the equipment configuration matches your production goals:

1.Clarify the Feed Type and Process Route

Shrimp feed production mainly uses two methods: pelleting and extrusion Pelletingtechnology is mature and requires less initial investment, suitable for producing sinkingshrimp feed: Extrusioh technology creates higher feed pellet density, better stability. andhigher digestibility, making it suitable for high-end feed production.

2. Determine Capacity and Automation Needs

Based on the plant size and market planning, select an appropriate production capacity (e.g., 1–10 tons/hour) to avoid overcapacity or undercapacity.

At the same time, decide between a fully automated or semi-automated system based on labor costs and management needs. The former is suitable for large-scale production, while the latter suits small and medium-sized farmers.

2. Determine Capacity and Automation Needs

Based on the plant size and market planning, select an appropriate production capacity (e.g., 1–10 tons/hour) to avoid overcapacity or undercapacity.

At the same time, decide between a fully automated or semi-automated system based on labor costs and management needs. The former is suitable for large-scale production, while the latter suits small and medium-sized farmers.

2. Determine Capacity and Automation Needs

Based on the plant size and market planning, select an appropriate production capacity (e.g., 1–10 tons/hour) to avoid overcapacity or undercapacity.

At the same time, decide between a fully automated or semi-automated system based on labor costs and management needs. The former is suitable for large-scale production, while the latter suits small and medium-sized farmers.

2. Determine Capacity and Automation Needs

Based on the plant size and market planning, select an appropriate production capacity (e.g., 1–10 tons/hour) to avoid overcapacity or undercapacity.

At the same time, decide between a fully automated or semi-automated system based on labor costs and management needs. The former is suitable for large-scale production, while the latter suits small and medium-sized farmers.

FREOUENTLY ASKED OUESTIONS

If you have any questions about shrimp feed maling machine or shrimp feed production line.

you can first take a look at these answers

In what situationsshould I buy a production line1?

1Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

In what situationsshould I buy a production line2?

2Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

In what situationsshould I buy a production line?

Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

In what situationsshould I buy a production line?

Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

In what situationsshould I buy a production line?

Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

In what situationsshould I buy a production line?

Whether you’re an individual farmer, aquaculture operator.feed processor, or feed manufacturer, you can choose to buya production line. Because we offer different sizes. our linesare suitable for many kinds of facilities.

If you want to produce finished feed in bags with little effort, we suggest buying a full line. lt allows automatic and continuous processing. which helps keep the feed quality consistent.

?

RICHI MACHINERY

Our business centers on aquatic feed machinery. We don’t just research, develop, and manufacture core equipment like fish feed extruders, fish/shrimp feed pellet machines, and pet food extruders. Plus, we offer complete feed production solutions, helping you set up fully

integrated plants for producing fish/shrimp feed or dog & cat food.

We offer our related services to so many feed producers worldwide. Our feed pelletizing equipment has been sold to more than 140 of the

more than 200 countries and regions in the world.

If you’re not interested in shrimp feed pellet production, feel free to explore the fields below.

Equipment Production

Equipment Production

Equipment Production

If you have any questions, please contact RICHI Machinery. Your dedicated customer service manager will

provide a one-stop and worry-free solution.