RICHI MACHINERY

FISH FEED MACHINE

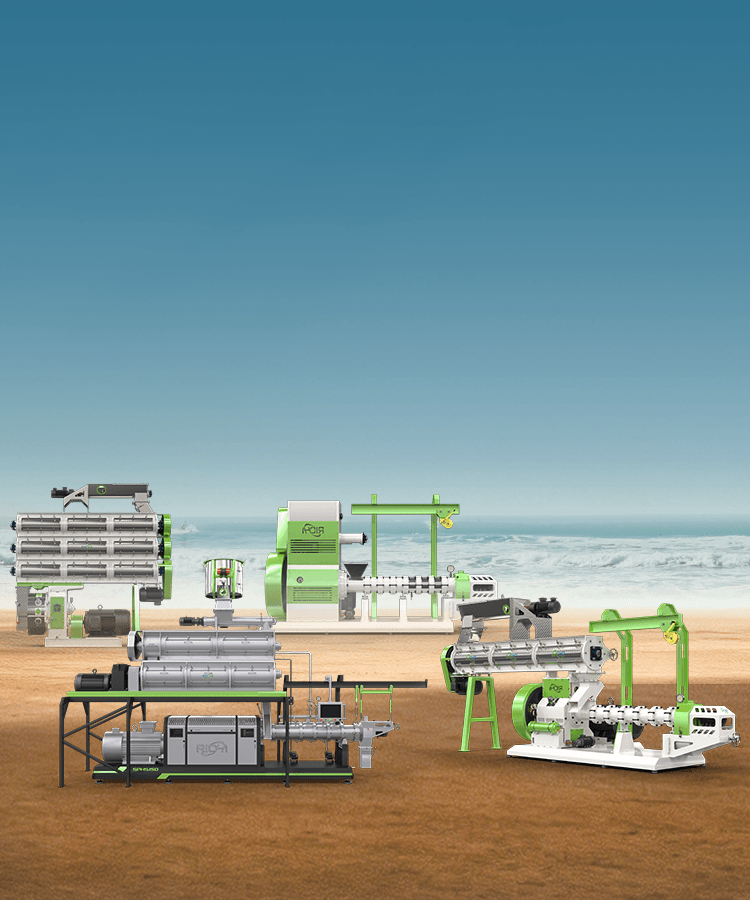

4 series fish feed fachines-sinking & foating feeds available

4 series fish feed fachines-sinking & foating feeds available

4 series fish feed fachines-sinking & foating feeds available

4 series fish feed fachines-sinking & foating feeds available

FISH FEED MACHINE

The model number of each fish feed machihe tells you its capacity and core performanceTake the DGp.90B dlytype fish fed extruderas an example. 90 represents the screw diameter. A biger diameter means higher output and stronger pressing force. This makes denser, morewater-resistant pellets-but also increases cost and energy use. Smaller diameters suit low-volume or sma-scale production and are more fiexible.

For fish feed pelet machines,”250 and”320″ show the ring die imner diameter. A larger imner diameter ghves higher pelet output and beter water resistance. Smaler models use less powerand cost less, but thei output is limited. This way, you can pick the best mocel for your production size and budget.

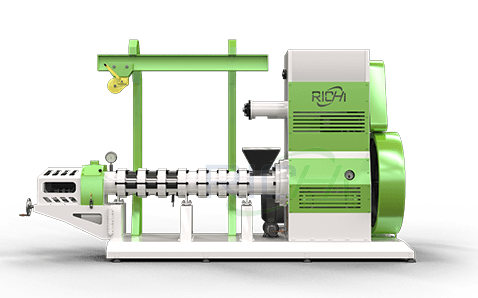

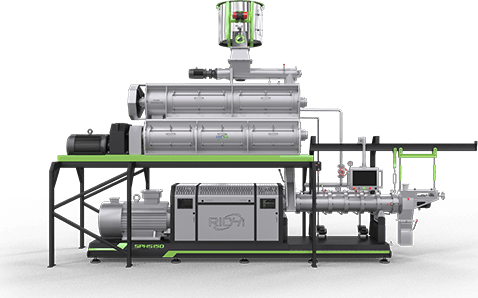

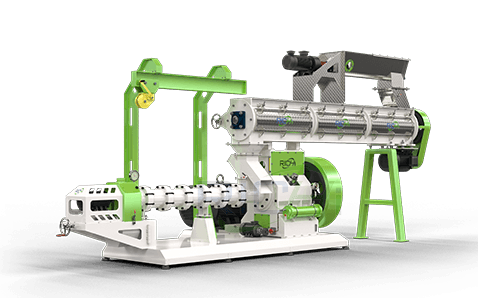

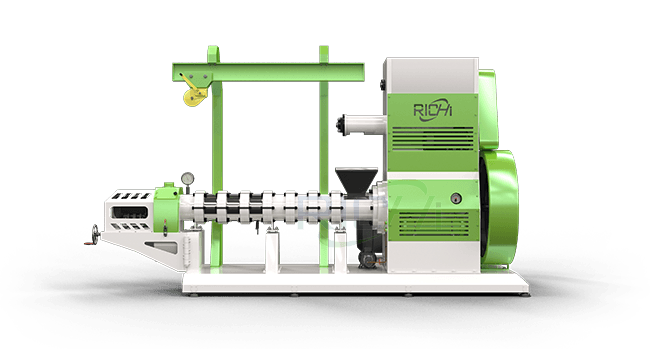

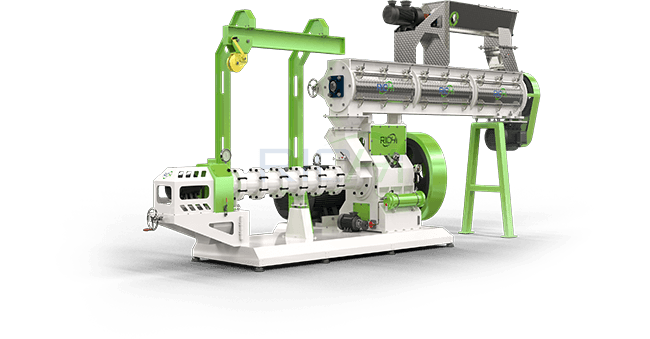

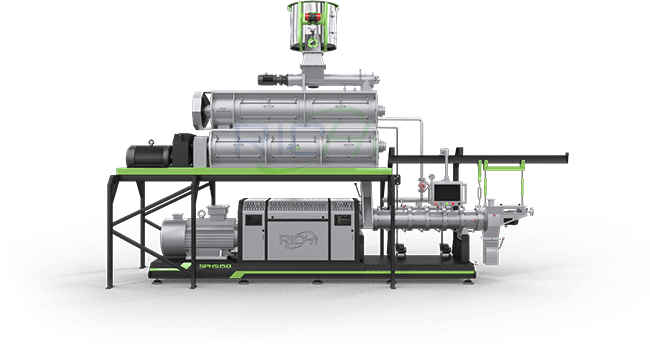

DGP Series Dry Type Extruder

Produces foating/sinking fish and shrimp feed, and pet food.

Price range: $8,000-$30,00

DGP-90B

DGP-90B

DGP-90B

DGP Series Dry Type Extruder

Produces foating/sinking fish and shrimp feed, and pet food.

Price range: $8,000-$30,00

DGP-90B

DGP-90B

DGP-90B

DGP Series Dry Type Extruder

Produces foating/sinking fish and shrimp feed, and pet food.

Price range: $8,000-$30,00

DGP-90B

DGP-90B

DGP-90B

DGP Series Dry Type Extruder

Produces foating/sinking fish and shrimp feed, and pet food.

Price range: $8,000-$30,00

SZLH420

SZLH420

SZLH420

SZLH420

SZLH420

SZLH420

SZLH420

SZLH420

FISH FEED MACHINE CAPACITY FOR OPTIONS

Of course, even if you’re not very familiar with the fish feed machines, just knowing your daily feed consumption is enough to choose the right fish feed mill.

Here we show several standard capacity models of fish feed equipment. Each type can be customized based on its minimum capacity.

Also, our fish feed machines can work with solar power systems (but cannot rely fully on solar)The system needs three-phase power to ensure stable operation.

FISH FEED MACHINE FOR FLOATING & SINKING FEED

Jhsure howto choose a fish fed machine? ustlok athe fsh’s feeding habts, Based ondiferent feding habits,lclfish fed machines are diided mto wotypes one for oating fed and anoher for sinkinged.To produce floalingfed,fshfed extnuderis typicay used. Through hight emperature, highr pressure expansion,the peets foatonthe water suface. for sinking fed, you canuse either fsh fed extruder olfish feed pelet machine. The pelets have a higher density and sink faster.choosing the ight fish feed equipment helbs you improve feed utization and farming eficiency.

Floating Fish Feed Machine

The extrusion technology of fish feed extruders is what ruly produces stable, high oating pelets. Extruders are the mainstream equipment formaking extruded foating feed.

Dry type fish feed extruder

Entry-level model, the first choice for conventional floating feed production.

Power: 55KW

Screw number:1

Dry type fish feed extruder

Entry-level model, the first choice for conventional floating feed production.

Power: 55KW

Screw number:1

Dry type fish feed extruder

Entry-level model, the first choice for conventional floating feed production.

Power: 55KW

Screw number:1

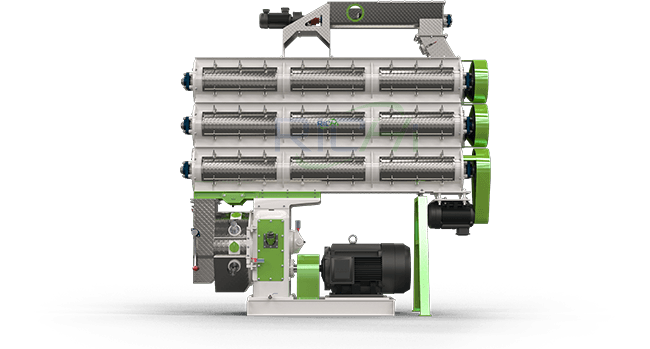

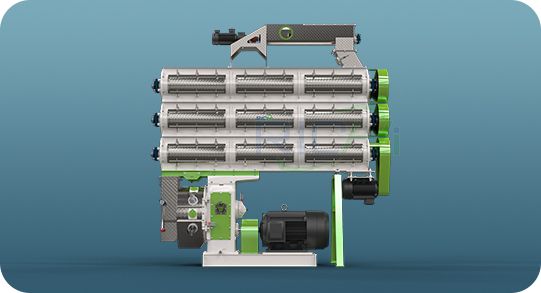

Sinking fish feed machine

From smalscale models to high output,featurerich equipment,sinking fish feed machines provide diverse coniguration solutions, including everything from ring die peet mils to various types of extruders.

Aqua Feed Pellet Machine Fish1

capacity: 0.6-30 tons/hour

Power:22-355 Kw

Aqua Feed Pellet Machine Fish1

capacity: 0.6-30 tons/hour

Power:22-355 Kw

Aqua Feed Pellet Machine Fish1

capacity: 0.6-30 tons/hour

Power:22-355 Kw

Aqua Feed Pellet Machine Fish1

capacity: 0.6-30 tons/hour

Power:22-355 Kw

FISH FEED MACHINE APPLICATIONS

Fish Feed Production Line

Mass-produces floating, sinking, and slow-sinking fish feed.

01 / 04

Fish Feed Production Line1

Mass-produces floating, sinking, and slow-sinking fish feed

Fish Feed Production Line2

Mass-produces floating, sinking, and slow-sinking fish feed

Fish Feed Production Line3

Mass-produces floating, sinking, and slow-sinking fish feed

Fish Feed Production Line1

Mass-produces floating, sinking, and slow-sinking fish feed

A fish feed machine can not only perform basic pelletizing on its own, but more importantly-When you want to scale up production,it can be integrated into a complete fish feed production line, working with proceses like grinding, mixing, dying,and oil

spraying, to achieve large-scale feed output.

Because it’s so flexible, we have full feed production line plans ready for different types of feed:

SINKING FISH FEED MACHINE

Standard fish feed production process has 8 stagesraw material processing – crushing + mixing – pelleting or extrusion – drying – spraying – cooling and screening – packaging.Iinfed mils,this procesisthe core ofproduction.Eachstagedrectly afectsthefna feed’s quaty and ouput fed plants of diferentsizes wilmake smaladjustments oradremove equipment based ontheir needs. This customizable design concept is what RicHl focuses on most when planning production lines for clients.

01 Raw Material Processing

Evenly blends various raw materials, allowing addition of additives or oils.

Equipment: Feed Mixer

Learn more →

01 Raw Material Processing

Evenly blends various raw materials, allowing addition of additives or oils.

Equipment: Feed Mixer

Learn more →

01 Raw Material Processing

Evenly blends various raw materials, allowing addition of additives or oils.

Equipment: Feed Mixer

Learn more →

01 Raw Material Processing

Evenly blends various raw materials, allowing addition of additives or oils.

Equipment: Feed Mixer

Learn more →

SINKING FISH FEED MACHINE

Standard fish feed production process has 8 stagesraw material processing – crushing + mixing – pelleting or extrusion – drying – spraying – cooling and screening – packaging.Iinfed mils,this procesisthe core ofproduction.Eachstagedrectly afectsthefna feed’s quaty and ouput fed plants of diferentsizes wilmake smaladjustments oradremove equipment based ontheir needs. This customizable design concept is what RicHl focuses on most when planning production lines for clients.

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

South Africa

lran 1.5-2 tons/hour extrusion fish andshrimp feed production line

WHAT OTHER CUSTOMERS ARE ASKING

Richi Machinery develops and supplies all kinds of auxiliary equipment for feed mill plant, biomass pellet plant, fertilizer pellet plant and provides consulting, process integration, equipment manufacturing, automation, etc.

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

Steven

Pilot Project

Floating Fish Feed Machine

” Floating Fish Feed Machine “

FISH FEED MACHINE

MANUFACTURER-RICHI MACHINERY

We are profesional ish’shimp feed equipment manufaclurers. ithneaty 30 years of experence making fishshimp feed machines,a modem factoy oer 60.00 square melers large, many patened tech nologies, and an experienced after-sales team, we can conidently provide ful senice for gilobal aquatic fed plants – from singie machines to complete production line solutions.

60,000

m²

Total plant floorspace of 60.000 square meters

TOP10

Total plant floorspace of 60.000 square meters

140+

Total plant floorspace of 60.000 square meters

2000

+

Total plant floorspace of 60.000 square meters

hoosing RaCHl Wachinery means more than just reliable equipmest – it’s choosing a long-er pariner who understands aquaculture and feed production. with our technical strength, patenied innovations, and comprehenslve afer- sales service, we support your faming and leed manufactuning every step af the way.

Our Standalone Equipment

Works with various raw materials, supports floating, sinking, and slow-sinking feedand allows flexible pellet size adjustment, Output can be customized, operation issimple, and daily main tenance is easy.The optimized design ensures lower energy consumption while maintaining high output.

Our Standalone Equipment

Works with various raw materials, supports floating, sinking, and slow-sinking feedand allows flexible pellet size adjustment, Output can be customized, operation issimple, and daily main tenance is easy.The optimized design ensures lower energy consumption while maintaining high output.

Our Standalone Equipment

Works with various raw materials, supports floating, sinking, and slow-sinking feedand allows flexible pellet size adjustment, Output can be customized, operation issimple, and daily main tenance is easy.The optimized design ensures lower energy consumption while maintaining high output.