Find What You Need

As long as you produce feed pellets for aquatic animals, RICHI can provide you with the correct selection of pellet equipment and professional production line planning. Our production line has scientific design and reasonable process, supports customization, and can flexibly process various raw materials; Single pellet machine equipment has high degree of automation, stable operation and strong applicability, and can accurately meet the feed production needs of different aquatic animals. From equipment to solutions, RICHI can help you succeed in the feed production industry in all aspects.

Aquatic Feed Production Line

ordinary feeds, such as those used for mixed pond fish, this

Aquatic Feed Production Line

ordinary feeds, such as those used for mixed pond fish, this

Aquatic Feed Production Line

ordinary feeds, such as those used for mixed pond fish, this

Aquatic Feed Production Line

Our aquatic feed production solutions are tailored to the growth characteristics and nutritional needs of aquatic animals such as fish and shrimp, as well as pets, to create comprehensive and efficient professional production lines. Can flexibly adapt to the customization demand of medium-sized farms and the mass production target of large-scale breeding bases.

Nutrient Retention

This line is designed specifically for aquaculture of fish species that require floating pellets, such as tilapia, common carp, and grass carp. By precisely controlling the temperature, humidity and pressure, the entire feeding waste, but also facilitate the fish to float to feed.

Nutrient Retention

This line is designed specifically for aquaculture of fish species that require floating pellets, such as tilapia, common carp, and grass carp. By precisely controlling the temperature, humidity and pressure, the entire feeding waste, but also facilitate the fish to float to feed.

Nutrient Retention

This line is designed specifically for aquaculture of fish species that require floating pellets, such as tilapia, common carp, and grass carp. By precisely controlling the temperature, humidity and pressure, the entire feeding waste, but also facilitate the fish to float to feed.

Nutrient Retention

This line is designed specifically for aquaculture of fish species that require floating pellets, such as tilapia, common carp, and grass carp. By precisely controlling the temperature, humidity and pressure, the entire feeding waste, but also facilitate the fish to float to feed.

Nutrient Retention

This line is designed specifically for aquaculture of fish species that require floating pellets, such as tilapia, common carp, and grass carp. By precisely controlling the temperature, humidity and pressure, the entire feeding waste, but also facilitate the fish to float to feed.

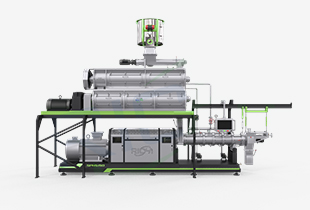

Aquatic Feed Production Line

Our aquatic feed production solutions are tailored to the growth characteristics and nutritional needs of aquatic animals such as fish and shrimp, as well as pets, to create comprehensive and efficient professional production lines. Can flexibly adapt to the customization demand of medium-sized farms and the mass production target of large-scale breeding bases.

Auxiliary Equipment

Auxiliary equipment looks unremarkable, but it’s an indispensable part of the entire production line. Raw materials are transported to the processing point by conveyors, different raw materials are mixed by mixers, hot pellets are cooled and shaped by cooling equipment, unqualified scraps are removed by screening equipment, and finally, the finished product is sealed by packaging equipment. These key links are indispensable. They work together with main pellet equipment to ensure the efficient operation of the entire production process and the quality of the final product.

Global Market

After decades of development, RICHI’s footprints have spread across numerous countries and regions around the world. It has consistently provided stable and reliable equipment and services to customers in various everywhere, winning wide recognition.

Get to know us

After nearly 30 years of technological accumulation and market expansion, the company has become more and more sophisticated on the road of integration of innovative design and industrial manufacturing. Today, our presence spans six continents, having successfully delivered thousands of projects for clients in over 130 countries. At RICHI, the belief that “your future is our future” has never wavered. From your initial consultation to final project delivery, we always take this belief as the guide, so that you can feel the seamless and intimate service in every link.

131+

Exporting Countries

131+

Exporting Countries

131+

Exporting Countries

131+

Exporting Countries

131+

Exporting Countries

131+

Exporting Countries

Owner Support

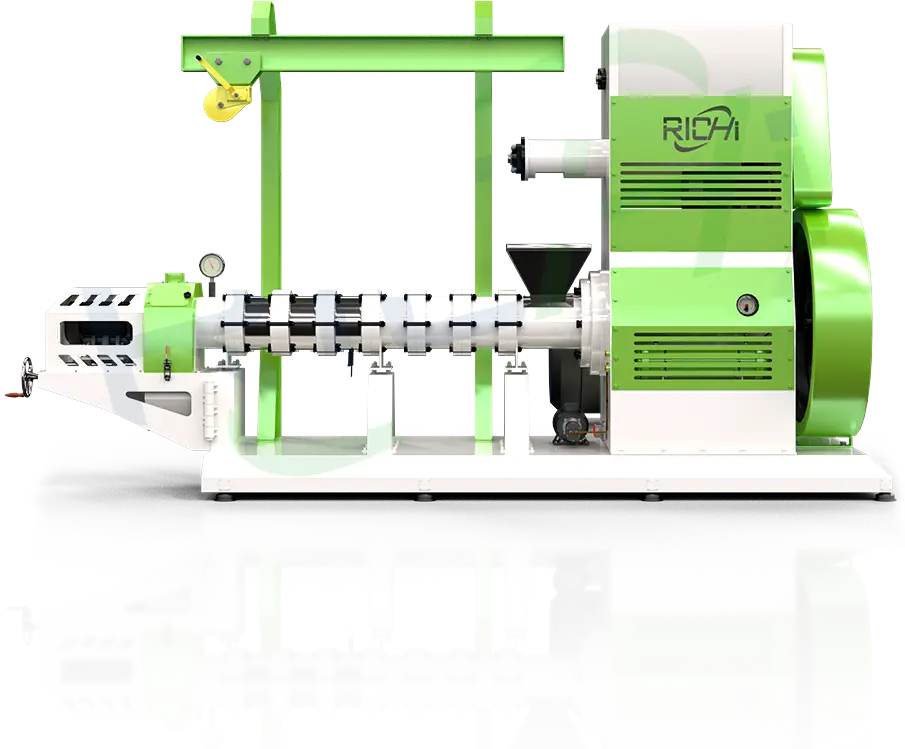

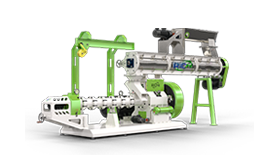

Equipment manufacturing

and customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have fish feed extruders, grinders, mixers, and cooling, drying and automatic packaging systems.

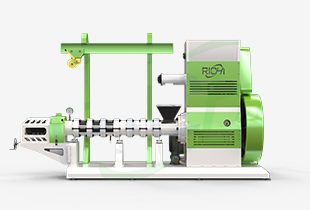

Equipment manufacturing

and customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have fish feed extruders, grinders, mixers, and cooling, drying and automatic packaging systems.

Equipment manufacturing

and customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have fish feed extruders, grinders, mixers, and cooling, drying and automatic packaging systems.

Equipment manufacturing

and customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have fish feed extruders, grinders, mixers, and cooling, drying and automatic packaging systems.

Equipment manufacturing

and customization

Whether you are a new feed factory or want to upgrade and expand production, we have corresponding solutions. In terms of equipment, we have fish feed extruders, grinders, mixers, and cooling, drying and automatic packaging systems.