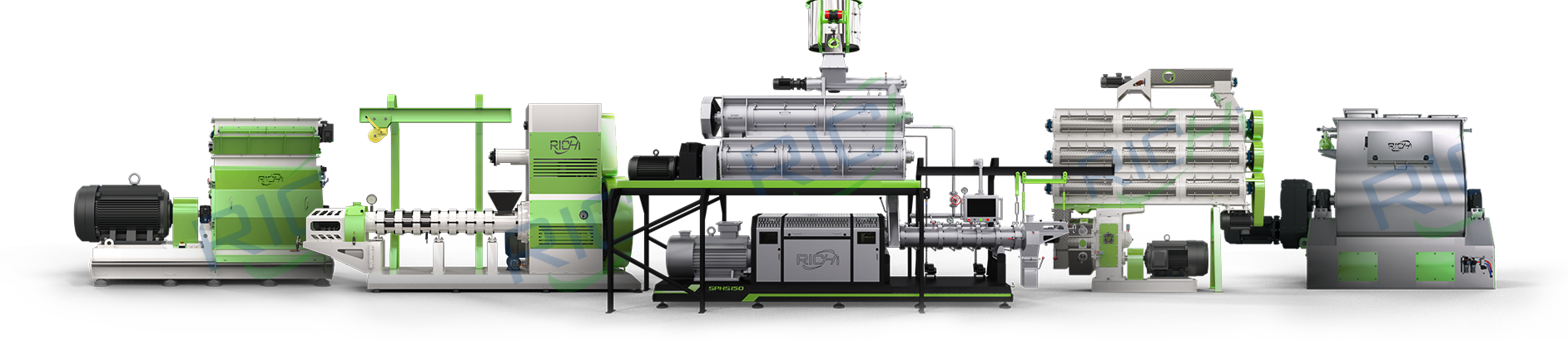

FISH FEED MAKING MACHINE

Each fish feed making machine from RICHI Machinery is built with care–they make your feed production easy and smooth. And we also offer custom fish feed production line solutions, helping you find the perfect solution for your factory.

START AQUACULTURE WITH THE START

AQUACULTURE WITH THE RICHT FISH FEED MACHIN

Do you want to make aquaculture easier and more efficient?

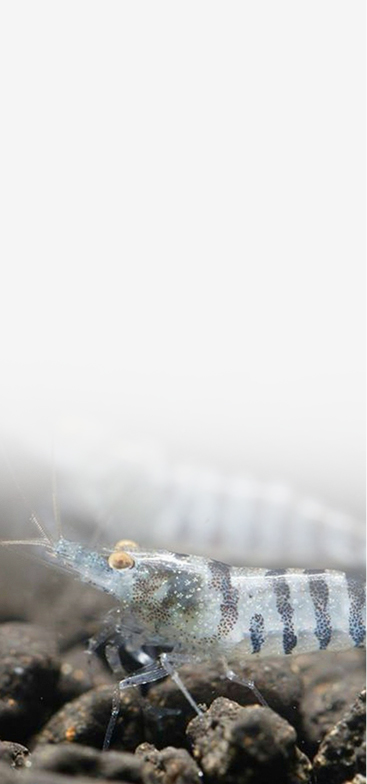

Do you want your fish and shrmp to grow happily in a comfortable and healthy environment?

Would you like to easily make high -quality fish feed every day whie saving labor and time?

Looking for a manufacturer that truly understand s

aquaculture feed and can help you build an entir fish feed production line?

RlCHl Machinery has many years of experience manufacturing fish feed machinery. We areconstantly improving our aquaculture feed extrusion technology, aquaculture feed pelletingsystems, aquaculture feed drying systems, and aquaculture feed spraying technologies toprovide you with more professional aquaculture feed production solutions andhelp you solve the challenges you encounter in fish feed production. We hope to use thoughtfudesigns and complete solutions to make fish feed production smooth and efficient for everyfarmer, ensuring that fish and shrimp grow healthily in a comfortable environment.

WHAT EQUIPMENT COMPOSES FISH FEED MAKING MACHINE?

Many people think fish feed making machine is simply a fish feed machine, but this isn’t entirely true. If you’re planning to make your own fish feed or start a aqua feed processing plant, it’s worth getting a quick sense of the difference.

A fish feed pelletizer or extruder is just one part of the whole fish feed making process, primarily responsible for converting mixed powder into pellets. But the true fish feed making machine is a complete system. It covers everything from raw material processing and mixing to pelletizing, cooling, and drying. Although the equipment used in these steps is not pelletizer, the whole production process wouldn’t proceed smoothly without them, so we count them as fish feed making machines.

Aquatic Feed Pelletizing Equipment

We offer fish feed extruders and fish feed pellet machine suitable for a variety of recipes, as well as shrimp feed pellet machines and extruders. Whether it’s the conditioner on the extruder or the ring die on the pellet machine, we can flexibly configure it to meet your specific production needs. That way, whether you’re producing floating, sinking, or slow-sinking fish feed, you’ll find the right equipment here at RICHI.

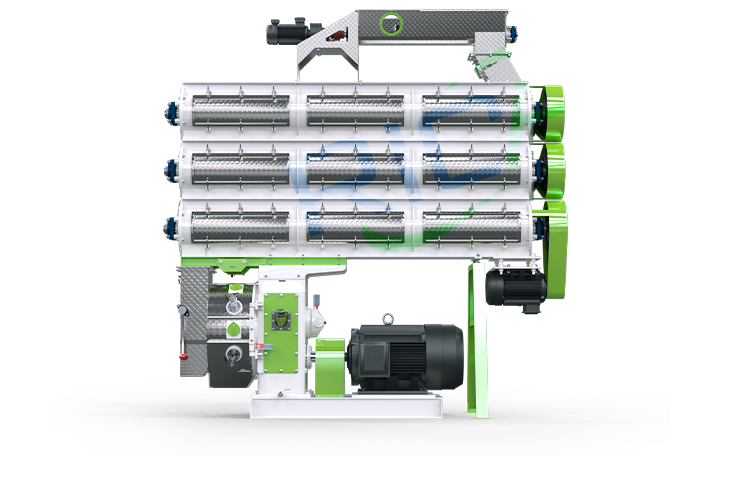

Fish Feed Pellet Machine

In addition to our standard pet food processing machines and equipment. RICHlMachinery also works with clients to develop customized machines andequipment, We also design, engineer, manufacture, install, and service completepet food

Output: 0.5-30 tons/hour

Power:22-315 KW

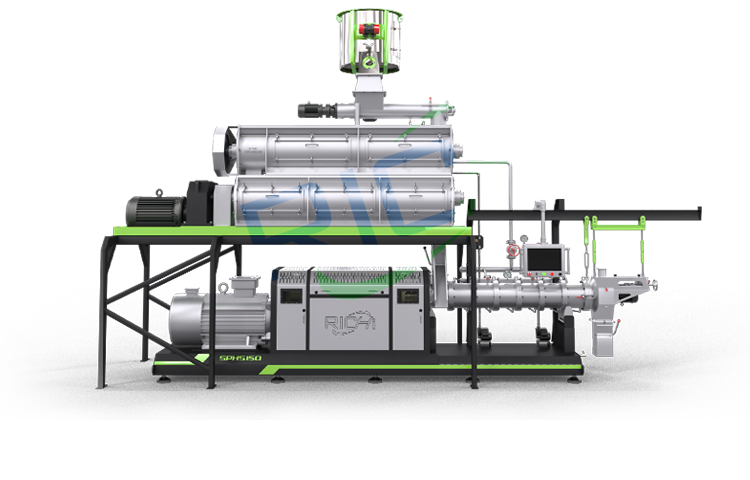

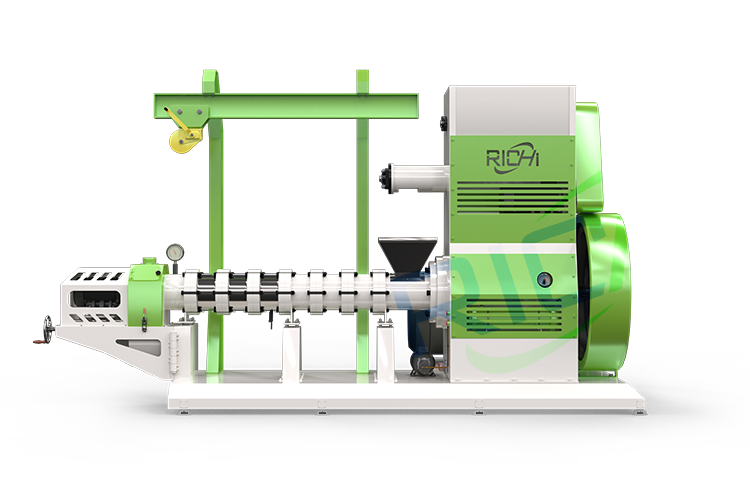

Fish Feed Extruder

In addition to our standard pet food processing machines and equipment. RICHlMachinery also works with clients to develop customized machines andequipment, We also design, engineer, manufacture, install, and service completepet food

Output: 0.3-12 tons/hour

Power:15-355 KW

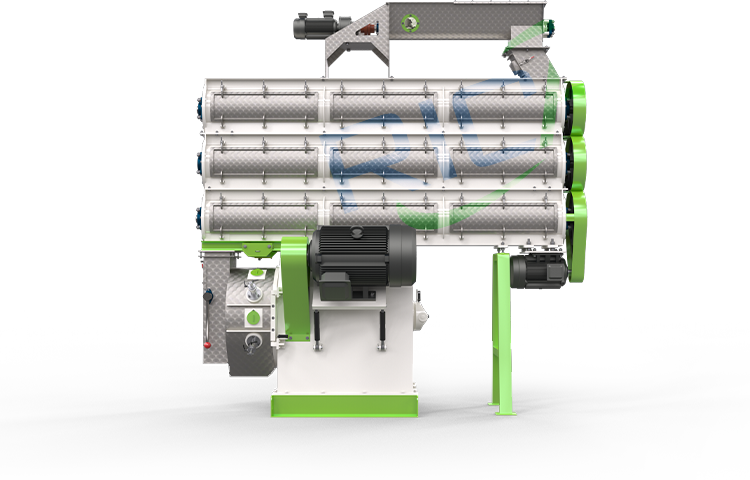

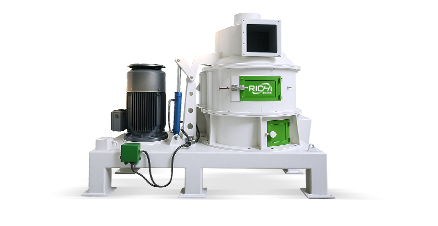

Shrimp Feed Pellet Machine

In addition to our standard pet food processing machines and equipment. RICHlMachinery also works with clients to develop customized machines andequipment, We also design, engineer, manufacture, install, and service completepet food

Output: 0.5-10 tons/hour

Power:22-355 KW

Pet Food Extruder

In addition to our standard pet food processing machines and equipment. RICHlMachinery also works with clients to develop customized machines andequipment, We also design, engineer, manufacture, install, and service completepet food

Output: 0.3-12 tons/hour

Power:15-355 KW

Fish Feed Production Auxiliary Equipment

When you are producing fish feed, the work of auxiliary equipment is not as intuitive as that of fish feed pellet mill. These equipment may seem inconspicuous, but they enable the entire production line to run smoothly. If you didn’t have them, even the best pellet machine couldn’t turn raw materials into really high-quality feed. This is why auxiliary equipment is also essential in the entire production line.

Crusher

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Crusher

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Crusher

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Sprayer

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Cooler

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Screener

Crush large raw materials such as corn and soybean meal into uniform fine particles, which is convenient for subsequent mixing and granulation.

Applications of Fish Feed Making Machines

When making fish feed, only by choosing the right raw materials can the nutrition and taste of the pellets be good. Take stuff like corn, soybean meal, fish meal, wheat bran, rapeseed meal—they might seem plain, but after being crushed, mixed, squeezed, and turned into pellets, they become feed that either floats, sinks, or sinks slowly. Whether it’s ornamental fish, tilapia, carp, carp, or pickier creatures like shrimp, crabs, turtles—even small pets–there’s a suitable feed for them.

wheat

wheat

wheat

wheat

wheat

wheat

More raw materials

More raw materials

wheat

wheat

wheat

wheat

wheat

wheat

WHERE FISH FEED MACHINES ARE COMMONLY USED?

RICHI’s fish feed making machines can meet the diverse needs of scaled-up aquaculture operations to large-scale professional feed mills.

Currently, our fish feed machines are primarily used in fish feed factories, aquaculture farms, pet food factories, and other feed mills.

Fish Feed Factory

We offer one-stop solutions for fish feed production—from designing the initial production plan to making, manufacturing, and installing the equipment. We’ll help you get your fish feed business up and running quickly.

Fish Feed Factory

We offer one-stop solutions for fish feed production—from designing the initial production plan to making, manufacturing, and installing the equipment. We’ll help you get your fish feed business up and running quickly.

Fish Feed Factory

We offer one-stop solutions for fish feed production—from designing the initial production plan to making, manufacturing, and installing the equipment. We’ll help you get your fish feed business up and running quickly.

Fish Feed Factory

We offer one-stop solutions for fish feed production—from designing the initial production plan to making, manufacturing, and installing the equipment. We’ll help you get your fish feed business up and running quickly.

FISH FEED MAKING MACHINE: WHAT PRODUCTION LINES CAN IT BUILD?

We leverage our expertise to meet your production needs and help you quickly launch your fish feed production business.

Based on the buoyancy characteristics of aquatic feeds, we offer both floating and sinking fish feed production lines. We also provide shrimp feed production solutions and pet feed production solutions.

Our uniquely designed fish feed pellet production solutions are designed to best meet your production needs.

Floating Fish Feed Production Line

We have built numerous sinking fish feed pellet machines around the world. Regardless of your project’s location, we can provide you with the necessary support.

Sinking Fish Feed Production Line

We have built numerous sinking fish feed pellet machines around the world. Regardless of your project’s location, we can provide you with the necessary support.

Shrimp Feed Production Line

We have built numerous sinking fish feed pellet machines around the world. Regardless of your project’s location, we can provide you with the necessary support.

COMPLETE SHRIMP FEED PRODUCTION PROCESS

When shrimp feed mill produce shrimp feed pellet, they usually use complete shrimp feed pellet lineBecause using complete shrimp feed production line to produce shrimp feed pellet can significantlyimprove the production efficiency of shrimp feed pellet and the quality of shrimp feed pellet.With rich experience, RiCHl carefully designs complete shrimp feed pellet line for shrimp feed mill andcreates turnkey shrimp feed production projects

The process flow of a standard fish feed production line:

01

Raw Materials Handling

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

01

Receiving and handling of raw materials

Receive, clean and store raw materials according to feed formula

WHICH FISH FEED MAKING MACHINE SHOULD I CHOOSE FOR DIFFERENT PRODUCTION CAPACITIES?

RICHI understands that fish feed factories of varying sizes have significantly different production capacity requirements. Therefore, we’re not limited to providing a single, standardized piece of equipment. Instead, we comprehensively consider multiple factors, including precise capacity adaptation, efficient plant space utilization, balancing initial investment with long-term costs, and allowing for future capacity expansion, to design a tailored solution for each customer.

We’ve prepared several fish feed making machine solutions; please compare them to see which one best suits your needs. Of course, if you have specific ideas or requirements, we can also design a customized solution based on your factory’s specific circumstances and desired production goals, ensuring that the equipment and production line are perfectly tailored to your exact needs.

FISH FEED MAKING MACHINE PROJECT CASES

With a truly global footprint, RICHI has successfully delivered numerous feed production projects across over 140 countries and regions worldwide—covering floating fish feed, sinking fish feed, poultry feed, chicken feed, cattle feed, shrimp feed, and more.

No matter what type of feed pellets you aim to produce, what raw materials you use, or where your facility is located, RICHI leverages its extensive practical experience to provide tailored feed pellet production solutions. Partner with us to unlock the potential of feed pellet manufacturing.

1-2 t/h Floating Feed Production Line In Indonesia

The customer built this fish feed factory to produce fish feed for its own aquaculture farms and also sell part of the fish feed to make a profit.After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so he signed a contract with us after finalizing the design plan.

- Feed Type: Floating fish feed pellets, shrimp feed pellets

- Main equipment :

2 t/h aquatic feed production line in Iran

The customer built this fish feed factory to produce fish feed for its own aquaculture farms and also sell part of the fish feed to make a profit.After the customer contacted us, he quickly determined that we were a professional aquatic feed pellet machine manufacturer, so he signed a contract with us after finalizing the design plan.

- Main raw materials : straw*20000ta, mainly flax straw

- Main equipment :

1-2 t/h Floating Feed Production Line In Indonesia

This fish feed pellet production line is located in Indonesia and is primarily used to produce floating fish feed. The client, considering local market conditions, observed increasing demand for fish feed and improving quality requirements. Believing the fish feed market to be relatively large and promising, they decided to invest in this sector. The client visited our factory to discuss the construction of a fish feed production plant, ultimately entering into a partnership.

- Main raw materials : straw*20000ta, mainly flax straw

- Main equipment :

1-2 t/h Floating Feed Production Line In Indonesia

This fish feed pellet production line is located in Indonesia and is primarily used to produce floating fish feed. The client, considering local market conditions, observed increasing demand for fish feed and improving quality requirements. Believing the fish feed market to be relatively large and promising, they decided to invest in this sector. The client visited our factory to discuss the construction of a fish feed production plant, ultimately entering into a partnership.

- Main raw materials : straw*20000ta, mainly flax straw

- Main equipment :

WHY DO CUSTOMERS AROUND THE WORLD CHOOSE RICHI?

RICHI Machinery has been deeply involved in the pellet machinery industry for nearly 30 years. Every piece of equipment we produce has passed international certifications such as ISO, CE, SGS, and BV, so you really don’t have to worry about quality. And every machine gets rigorously polished and tested before it leaves the factory. So we are confident they will withstand the test of real-world production.

Thanks to our long-standing technical experience and superior equipment quality, we can handle all kinds of pellet needs—floating, sinking, slow-sinking, you name it. Plus, we’ll design a full, efficient production plan just for you, based on your output, raw material formulas, and process requirements. We’ve got a wide range of equipment too. Besides aquatic feed pellet machines, we’ve got regular feed pellet equipment, wood pellet machines, organic fertilizer pellet machines. Right now, our products are exported to over 100 countries and regions, and customers have been really happy with them.

And it’s not just about reliable equipment—our service is top-notch too. From helping you select the right machine, to on-site installation and commissioning, teaching your operators how to use it, and even regular maintenance—our professional team’s got your back every step of the way. Just reach out whenever you need anything—we’re here!

1995

Export Countrice

10000+

More than 10000 square meter smodern factories

1995

Export Countrice

1995

More than 80 sets ofintemational advanced manufacturing equipment

Frequently Asked Questions

If you have any questions about extruders or feed production, you can first take a look at these answers.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.

As a farmer, I don’t know whether I should purchase a production line?

+

In fact, whether you are a farmer, an aquaculture operator, a feed processing company or a feed manufacturer, you can choose to purchase a production line. Because our production lines have many different output levels and can be adapted to different production scenarios.

So you don’t need to worry about what to do if you don’t have a suitable fish feed production line. The production line can be customized according to the production volume requirements, the size of the site, and the budget. Under suitable external conditions, we still recommend that you purchase a production line because the production line can achieve automated production and continuous processing, and can maintain the consistency of feed quality.