5-ton-per-hour

fish feed production line

in Russia

Feed Specifications:

0.5-8mm

Feed Specifications:

Bran, rice bran, soybean meal,silkworm pupa powder, meat and bone meal, salt, plus oils, vitamins, premixes, etc.

Feed Specifications:

Production of sinking and

floating fish feed

Feed Specifications:

Fully Automated Fish Feed

Production Line (Turnkey Project)

Feed Specifications:

5T/H

RUSSIAN AQUACULTURE MARKET

In recent years, Russia’s aquaculture industry has experienced rapid growth.expanding from inland freshwater ponds to coastal farming bases. Operationshave become increasingly large-scale, with the range of fish species cultivatedgrowing more diverse and high-end, Concurrently, local demand for fresh.premium aquatic products continues to rise, providing farmers with greaterincentive to expand production.

However, no matter how rapidly the market grows

one persistent challenge remains: high-quality fish feed consistently fails tomeet demand, On one hand, there is a shortage of good feed supplies; onthe other, existing feeds often suffer from uneven particle size, inconsistentnutritional stability, and susceptibility to spoilage during storage. These issuesdirectly undermine aquaculture profitability.

Therefore, an increasing number of experienced investorsare considering automated fish feed production lines.

one persistent challenge remains: high-quality fish feed consistently fails tomeet demand, On one hand, there is a shortage of good feed supplies; onthe other, existing feeds often suffer from uneven particle size, inconsistentnutritional stability, and susceptibility to spoilage during storage. These issuesdirectly undermine aquaculture profitability.

CLIENT PROJECT DETAILS

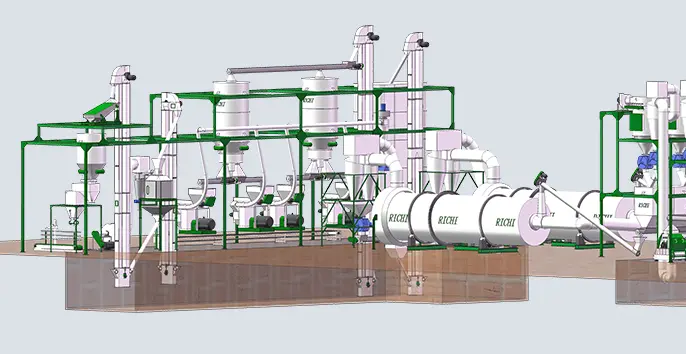

This project is located in Russia’s core aquaculture region, delivering a fully automated fish feedproduction solution tailored specifically for the local aquaculture market. The production linewe designed for this client focuses on mass-producing fish feed pellets, capable of consistentlyproducing floating pellets while primarily manufacturing sinking pellets-perfectly meeting themainstream demand for bottom-dwelling fish farming in Russia.

From the outset of their fish feed mill investment decision, the client explicitly sought “a$pecialized manufacturer with genuine expertise in aquafeed equipment.” For them. thisrepresented not only a significant capital investment but also a comprehensive “turnkeyproject requiring full entrustment. After comparing multiple manufacturers’ websites andreviewing past aquafeed production line case studies, the client recognized the advantagesof our equipment in terms of sinking pellet forming stability and production capacityadaptability, proactively initiating communication.

The formation rate of the water-sinkingmaterial exceeds 98% andit remains intact after soaking for 2 hours.

The formation rate of the water-sinkingmaterial exceeds 98% andit remains intact after soaking for 2 hours.

CUSTOM-TAILORED SOLUTIONS

When clients first discuss production line design with us, our engineers don’t start by presenting equipment specifications.instead, they ask: “What are your factory’s floor space dimensions, target production capacity, and the most pressing production challenges you aim to resolve?”

And so, through repeated discussions, the solution gradually takes shape.

How should the raw material receivingarea be planned to minimize transportation costs?

How should the raw material receivingarea be planned to minimize transportation costs?

How should the raw material receivingarea be planned to minimize transportation costs?

How should the raw material receivingarea be planned to minimize transportation costs?

The final fish feed production line primarily consists of the following components:

In aquaculture, high-quality feed is very important for fish to grow fast and stay healthy.If you plan to produce your own fish feed,

just using a dry type extruder is not enough. Because the extruder’s main job isonly to shape the feed into pellets, it

cannot complete many important steps before that.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

03

Mixing

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

RUSSIAN FISH FEED PRODUCTION LINE CONFIGURATION

When clients first discuss production line design with us, our engineers don’t start by presenting equipment specifications.Instead, they ask: “What are your factory’s floor space dimensions, target production capacity, and the most pressing productionchallenges you aim to resolve?”

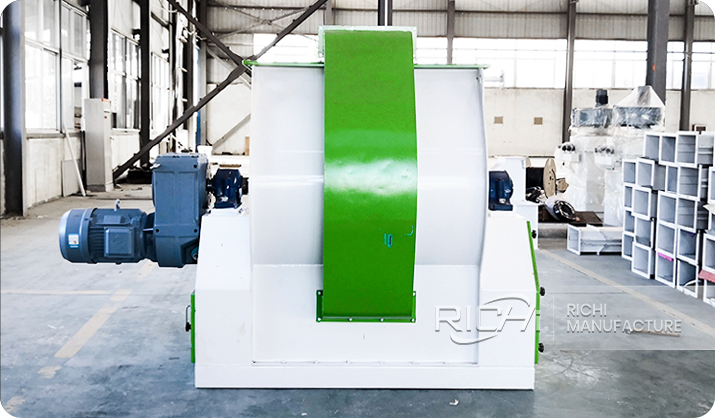

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

01

Crushing System

After cleaning and impurity removal, The raw materials for producinganimal feed only need to be crushed once. but the production offloating fish feed requires a higher particle size of the raw materials.which requires two crushings. The fineness of the crushed material isabout 1mm.

This feed pellet production proiect started investment and construction in 2019, After completion, the feed pellets produced have been quite ideal, and customers have always had a good relationship with us.

Nowadays, with the development of aquaculture, the requirements for aguatic feed are also increasing. The customer lateipurchased a spraying machine to increase the oil content of floating fish feed to meet the energy needs of fish growth.

And currently customers are discussing with us plans to expand feed production capacity.

HOW TO START YOUR FISH FEED PRODUCTION LINE PROJECT

‘pez!lees /liny s,+! l!un joofosd sno人 从!elo

o1 dais Ag dois no/ bu!p!n6 ‘*ouyed ino aq l,eM “ueis ay woyy bu!yihene puegsiepun o4 paou ,uop noA

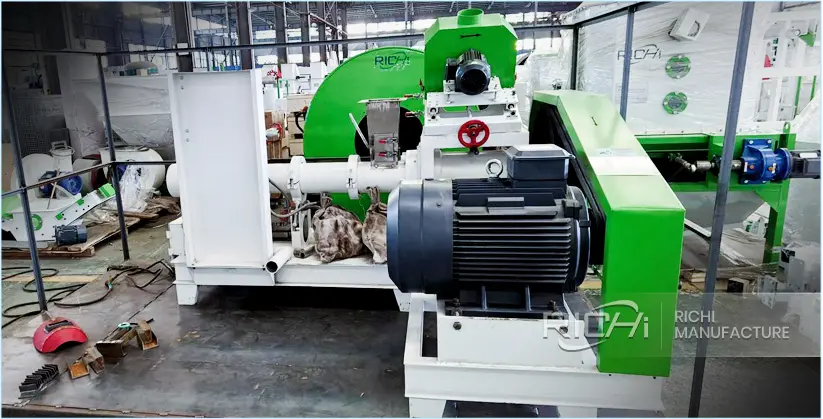

Machine Production

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Machine Production

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Machine Production

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Since this is a custom-built fish feed production line for our client, coreequipment such as extruders, crushers, and dryers are all manufacturedexclusively to meet their specific requirements. Therefore. once theproduction line plan is finalized and the contract signed. our factoryimmediately begins scheduling production for all necessary equipment.

Throughout the entire process, you don’t need to understand technology, design, or workflows, simplyshare your ideas with us, and we’ll handle the rest, Click the button below now to get in touch and takethe first step toward launching your project.

HOW TO START YOUR FISH FEED PRODUCTION LINE PROJECT

‘pez!lees /liny s,+! l!un joofosd sno人 从!elo o1 dais Ag dois no/ bu!p!n6 ‘*ouyed ino aq l,eM “ueis ay woyy bu!yihene puegsiepun o4 paou ,uop noA

The project manager responsible for constructing a 5-ton-per-hour fish feed production line in Kyrgyzstan highly praised our equipment during discussions with RiCHl’s after-sales service center staff:

For us. this fish feed plant represents not merely a production line. but a crucialohase in the development of Kyrgyzstan’s trout farming industry. Consequently.we have placed special emphasis on its construction.”

For us. this fish feed plant represents not merely a production line. but a crucialohase in the development of Kyrgyzstan’s trout farming industry. Consequently.we have placed special emphasis on its construction.”

For us. this fish feed plant represents not merely a production line. but a crucialohase in the development of Kyrgyzstan’s trout farming industry. Consequently.we have placed special emphasis on its construction.”

Operat onal Status

The completion of a 5-ton·per hour salmon feed production line in Kyrgyzstan not only fully meets the demand for salmon feed amongaquaculture enterprises but also avoids restrictions and issues associated with feed imports,. simultaneously, with the relentless developmentof the livestock industry, establishing their own stable feed factories has become an inevitable trend for large-scale aquaculture enterprisesto ensure the reliability and controllability of feed supply.

OUR PROJECTS IN OTHER COUNTRIES

The 5-ton-per-hour salmon feed production line project in Kyrgyzstan was successfully installed and put into operation by the end of 2023. The equipment operates stably, with production capacity meeting standards, Folowing project completion, we maintain close communication with the client to ensure timely supply of required spare parts and provide technical support for plant operations.

For 30 vears, RlCH has been dedicated to manufacturina fish feedequipment. We have established fish feed production lines in numerous countries and regions worldwide, including Kyrgyzstan, Kazakhstan,Ukraine, Uzbekistan, Azerbajan, Algeria, lran,lndia, Nigeria, and othersearning deep trust and high praise from our customers, fyou are planning to launch a fish feed production line project, please contact usRlCH will provide you with professional solutions and comprehensive technical services and support to help you efficiently launch production and quickly achieve profitability

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

1-2 Ton/Hour Ukrainian Fish Feed Production Line

For years. RiCHl has been actively engaged in the feedproduction sector in Ukraine and Kazakhstan, providing localcustomers with various feed production equipment andcomprehensive production solutions for broilers, livestock. fish.and other key sectors. This supports the development of localanimal husbandry and aquaculture production.

RICHI PROTECTION

Based on the customers site conditions, production requirements, and other needs, our professional engineers designed over ten solutions. Through continuous refinement of drawings,process modifications, and incorporation ofspecial designs, we ultimately customized a solution that fuly meets the customer’s production demands

Custom Design

Based on the client’s site conditions, production requirements, and other specifications, our professional engineers developed over ten tailored solutions.Through continuous refinement of drawings, process modifications, and specialdesian additions, we ultimately customized a solution that fully meets the client’s production needs.

Custom Design

Based on the client’s site conditions, production requirements, and other specifications, our professional engineers developed over ten tailored solutions.Through continuous refinement of drawings, process modifications, and specialdesian additions, we ultimately customized a solution that fully meets the client’s production needs.

Custom Design

Based on the client’s site conditions, production requirements, and other specifications, our professional engineers developed over ten tailored solutions.Through continuous refinement of drawings, process modifications, and specialdesian additions, we ultimately customized a solution that fully meets the client’s production needs.

Custom Design

Based on the client’s site conditions, production requirements, and other specifications, our professional engineers developed over ten tailored solutions.Through continuous refinement of drawings, process modifications, and specialdesian additions, we ultimately customized a solution that fully meets the client’s production needs.

WHAT FEED PROCESSING SOLUTIONS CAN WE PROVIDE?

We can design and buld complete feed pellet production lines and turnkey feed pelet mills with hourly capacities ranging from 1 to 100 tons for al types of aquatic organisms and animals.

Aquatic Feed Production Line

Conventional aquaculture species including fish, shrimp. crab, shellfish, and specialty aquatic animals

Aquatic Feed Production Line

Cats. dogs. hamsters. turtles..

Aquatic Feed Production Line

Cats. dogs. hamsters. turtles..

Aquatic Feed Production Line

Cats. dogs. hamsters. turtles..

Aquatic Feed Production Line

Cats. dogs. hamsters. turtles..