FISH FEED PROCESSING LINE

1.0-2.0 T/Hfish Feed Production

Richi Machinery specializes in the research and development of fish feed processing lineequipment, equipped with advanced processing technology and strict quality supervisionsystem guarantee, and can tailor-made fish feed line to meet various performanceregquirements. in addition to fish feed, if you want to process shrimp feed, livestock andpoultry feed, pet feed, premix and other t

FISH FEED PROCESSING LINE

1.0-2.0 T/H fish Feed Production

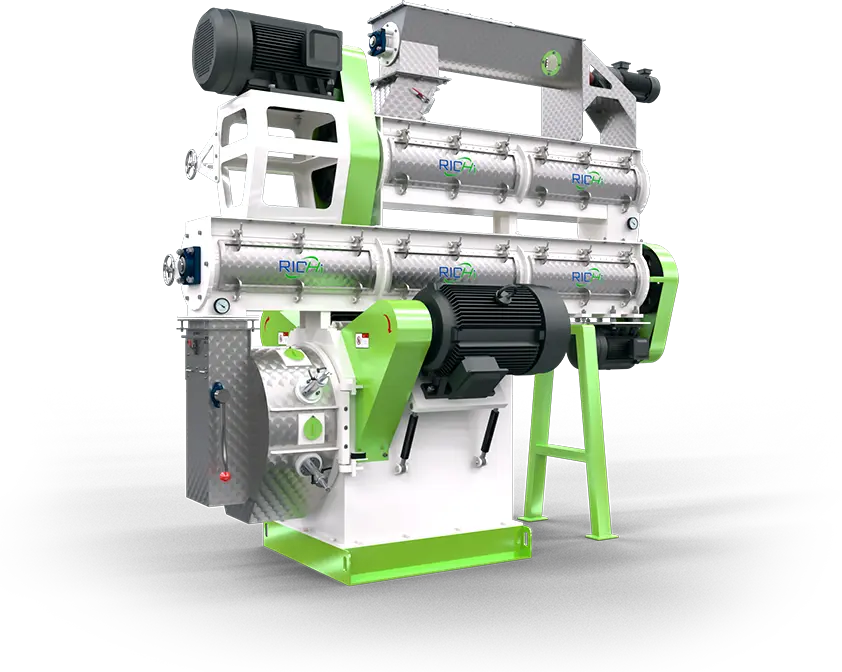

RiCHl 1-2t/h fish feed processing line adopts feed extruding/pelleting technology andis divided into low, medium, high and other design schemes, which are suitable for theprocessing of various types of floating fish feed, sinking fish feed, slow sinking fish feedmicro fish feed, etc.

As the world’s leading feed equipment, storage equipment and complete fish feedprocessing system service provider, in recent years, Richi Machinery has madecontinuous breakthroughs in the continuous promotion of core extrusion/pelletingtechnology construction, new product research and development, and expansion of market layout, especially in aquatic products.

fish feea Today, in more than 40 countries around the world, many 1-2t/h high-tech processing plants manufactured by RicHl are helping customers create a full range of high-end aquatic feeds.

Production capacity

(tons/hour)

1-2

Pellet size

(mm)

0.5-12

Maybe you are interested in other solutions :

| 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > |

| 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > | 0.1-1T/H > |

APPLICATION OF FISH FEED

PROCESSING LINE

Fish feed processing line can process floating fish feed, pet feed, and some high-endextruded feed for livestock and poultry. it can also be upgraded to a combined feedproduction line, process shrimp feed, crab feed, eel feed, pet food livestock andpoultry feed, premix and other products at the same time.

It is usually invested and built by fish feed factories, aquatic feed factories, petfeed factories, compound feed factories, fish farms, aquatic processing plants.etc. Of course, there are also many investors from different industries who are veryoptimistic about the prospects of fish feed processing, so they enter the aquaticfeed processing industry.

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

Aqua feed mill

FISH FEED PROCESSING LINE

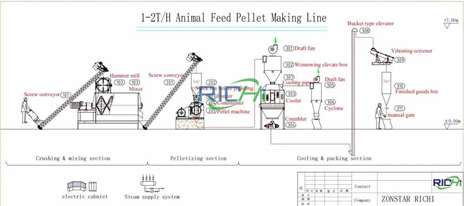

CUSTOMIZED POULTRY FEED PELLET PRODUCTION PROCESS DESIGN

Discover our products

1-2T/H FISH FEED PROCESSING LINE CONFIGURATION

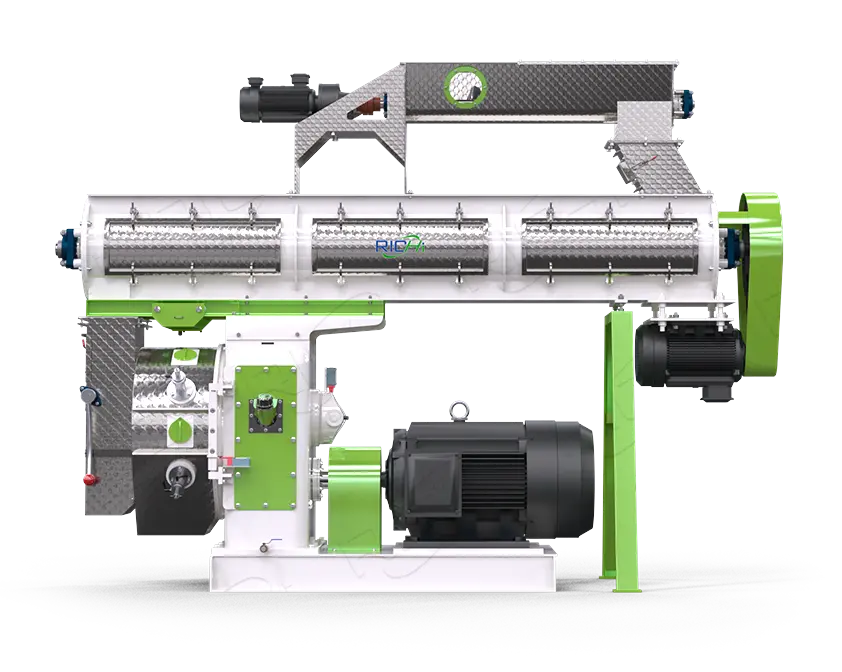

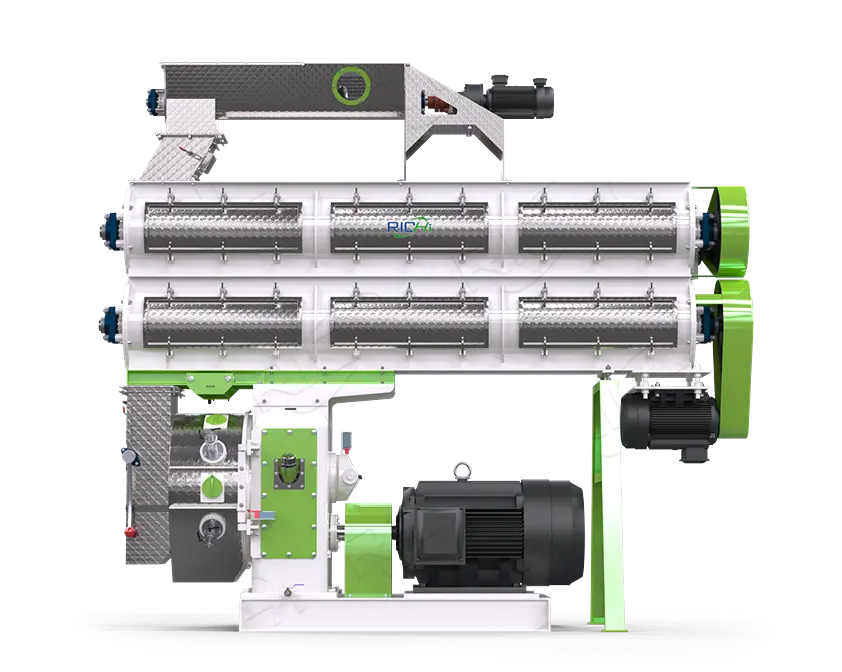

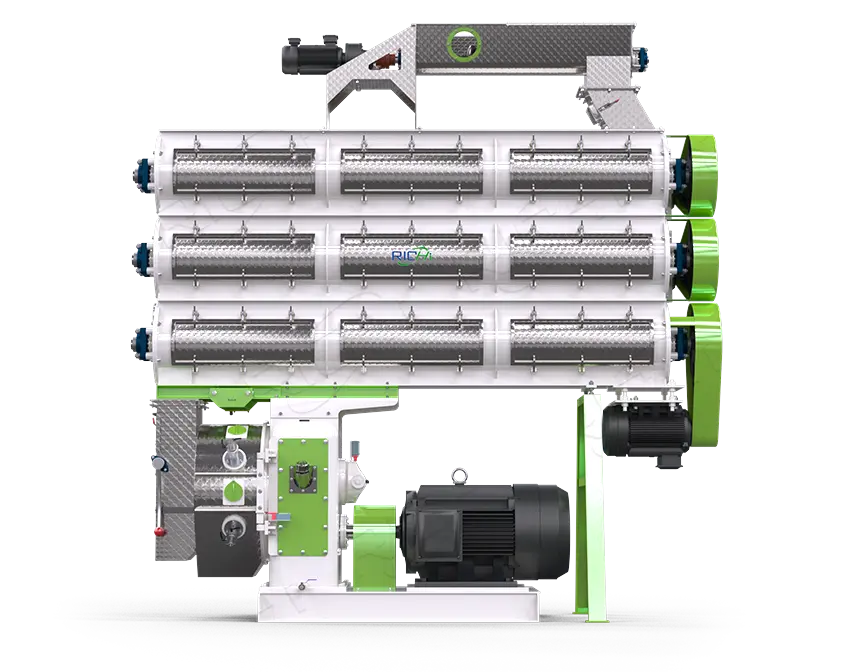

A fish feed processing line uses a lot of equipment, How to configure theseequipment into an efficient fish feed processing system is a professional matter.Because the equipment configuration depends on the process design of theproduction line, a full set of equipment can be configured after the process isdetermined. Here are the main equipment and models of a -2t/h twin screwtype fish feed line for you.

| Name | Model |

|---|---|

| Drum type precleaner | SCY63 |

| Permanent magnetic sleeve | TCXT20 |

| Screw conveyor | TLSS20 |

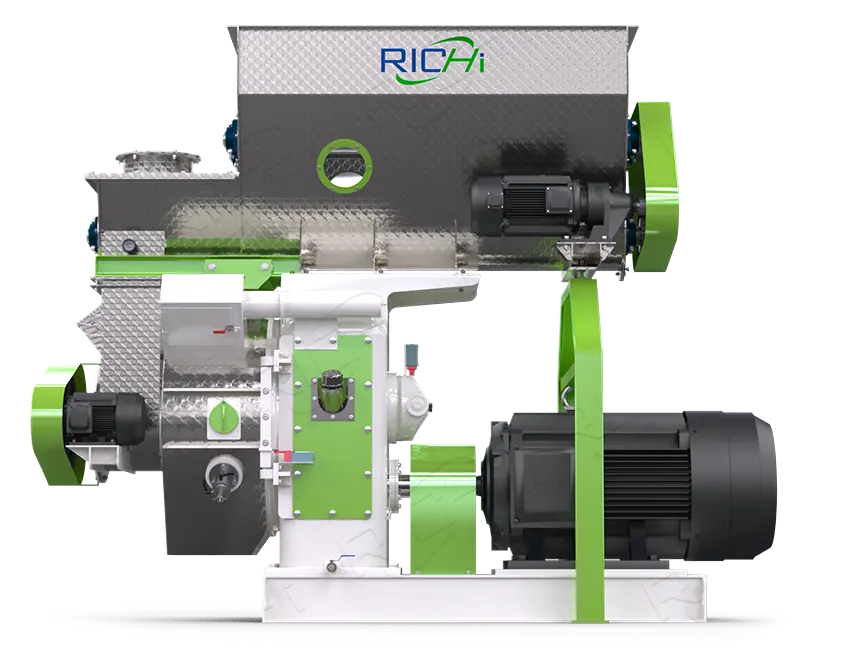

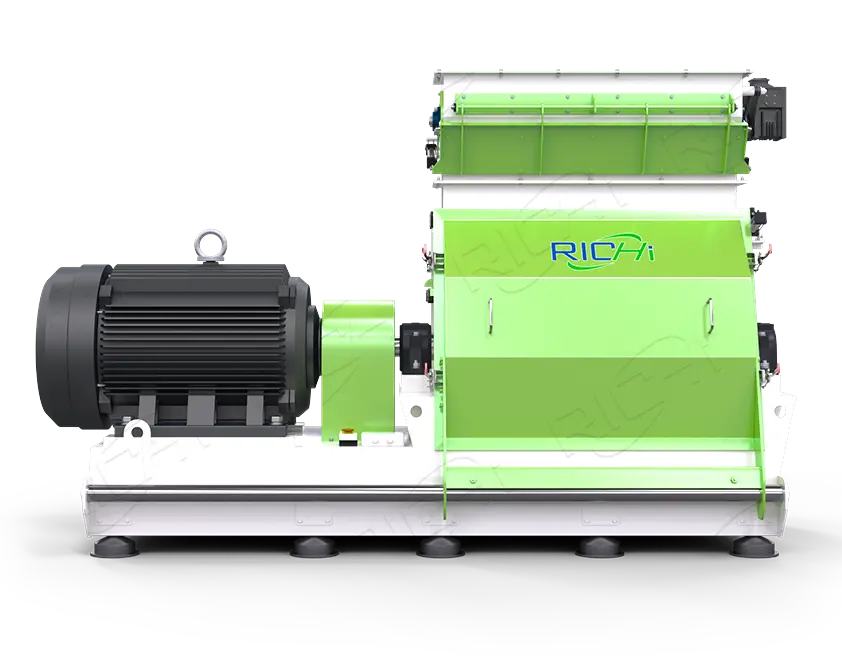

| Fish feed Hammer mill | SFSP66*60 |

| Pulse dust collector | TBLMa.24A |

| Bucket Elevator | TDTG36/8 |

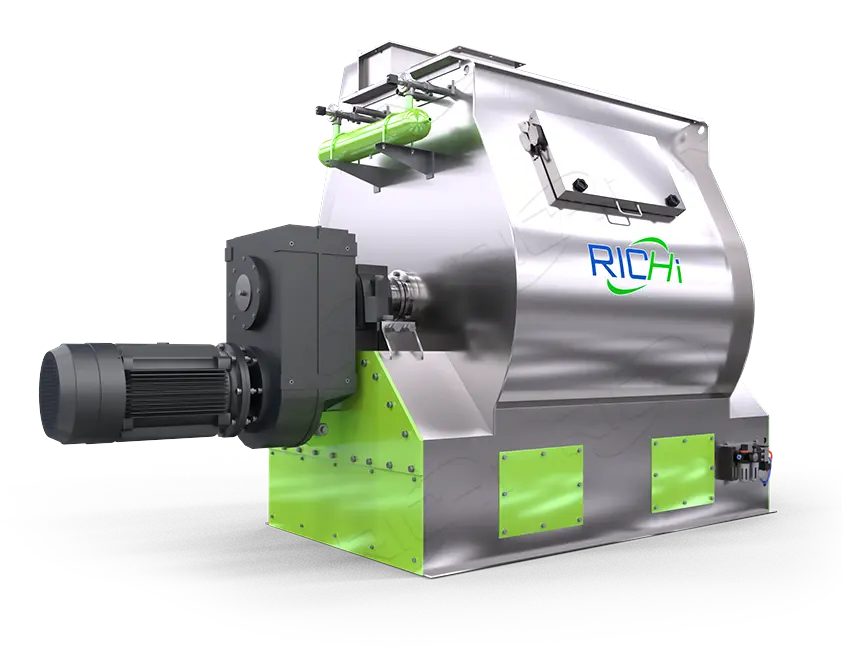

| Fish feed Mixing machine | SLHY1.OA |

| DDC-conditioner | DC400*300-244 |

| MCC Control Center :Mimic control panel (power range from 22 kw for star triangle start, main electric components are Siemens brand) | |

1-2 T/H FISH FEED PROCESSING LINE PROJECT

systems with an hourly outputAt present. wen 80 countres crounc the woric,cna naveof +2 tons in more thancountries include major aquaculture countries such as India.USA, Brazil, Ecuador. Vietnam,Bangladesh, Egypt, Chile and Philippines.

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

CUSTOMER TESTIMONIALS

At present we have established fish feed production ines in 80 countries around the world, and have established fish feed systemswith an hourly output of +2 tons in more than 40 countries.These countries include major aquaculture countries such as lindic, Russia,Indonesid, UsA, Brazil, Ecuador, vietnam, Bangladesh, Egypt, Chile and philippines.At present,we have estabished fish feed productionlines in 80 countries around the world, and have established fish feed

PROJECT VIDEO

RiCHl Machinery offers a diverse expertise to provide solutions for your feed factory construction,renovations, design/build, upgrades and engineering projects

Customer Testimonials

At present, we have established fish feed production lines in 80 countries around theworld, and have established fish feed systems with an hourly output of 1-2 tons in morethan 40 countries, These countries include major aquaculture countries such as india,Russia, indonesia, USA, Brazil, Ecuador, Vietnam, Bangladesh, Egypt, Chile and Philippines.Atpresent, we have established fish feed production lines in 80 countries around the world,and have established fish feed systems with an hourly output of 1-2 tons in more than40 countries. These countries include major aquaculture countries such as india, Russia,Indonesia, USA, Brazil, Ecuador, Vietnam, Bangladesh, Egypt, Chile and Philippines.At presentwe have established fish feed production lines in 80 countries around the world, and haveestablished fish feed systems with an hourly output of 1-2 tons in more than 40 countries.These countries include major aquaculture countries such as India, Russia, Indonesia, USABrazi, Ecuador, Vietnam, Bangladesh. Egypt

Project Video

RlCHl Machinery offers a diverse expertise to prgvide solutions for your feed factory constructionrenovations, design/build, upgrades and engineering projects. We begin with our customers keydesian criteria in mind. These include feed mill production

Other solutions we can do

RICHI floating fish feed machine is suitable for processing viscous,oily, and high-humidity aqua feed products, and can provide ideal solutions

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

THE PROSPECTS OF PROCESSED FISH FEED AND AQUAFEED

Private customized program design: customized designaccording to your budget,production, demand,and, plant, customer demand-oriented design to customizethemost suitable solution for you.

Private customized program design: customized designaccording to your budget,production, demand,and, plant, customer demand-oriented design to customizethemost suitable solution for you.

Private customized program design: customized designaccording to your budget,production, demand,and, plant, customer demand-oriented design to customizethemost suitable solution for you.

GE TTO KNOW US

RICHl Machinery offers a diverse expertise to provide solutions for your feed factory construction

renovations, design/build, upgrades and engineering projects. We begin with our customers keydesign criteria in mind. These include feed mill production

Technology R&D

With robust reliability and ease of operation, RICHI biomass pellet mill is backed by the best service and support teams in the agricultural and forestry waste pellet industries.

Technology R&D

With robust reliability and ease of operation, RICHI biomass pellet mill is backed by the best service and support teams in the agricultural and forestry waste pellet industries.

Technology R&D

With robust reliability and ease of operation, RICHI biomass pellet mill is backed by the best service and support teams in the agricultural and forestry waste pellet industries.

RICHl Machinery offers a diverse expertise to provide solutions for your feed factory construction

renovations, design/build, upgrades and engineering projects. We begin with our customers keydesign criteria in mind. These include feed mill production

Discover our products

Our wood pellet mils are built to the highest possible standards and designed tomake your job easier, safer

Evaluate

We want to have a deep understanding of your industrial process.

Evaluate

We want to have a deep understanding of your industrial process.

Evaluate

We want to have a deep understanding of your industrial process.

Evaluate

We want to have a deep understanding of your industrial process.

Evaluate

We want to have a deep understanding of your industrial process.

Evaluate

We want to have a deep understanding of your industrial process.