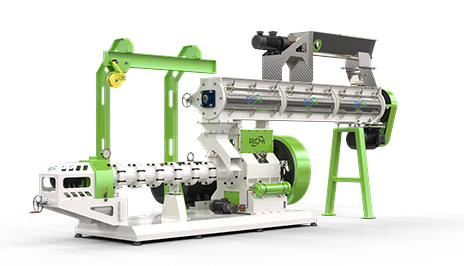

Floating Fish Feed Line

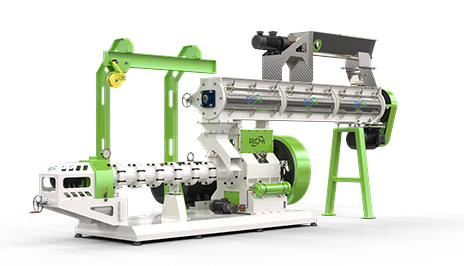

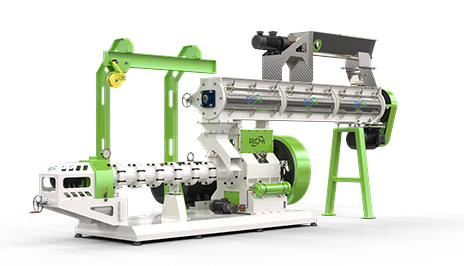

Floating fish feed machine manufacturer The latest extrusion technology enables you to produce the best floating aquafeed

Suitable Animals

The feed made by dry extruders is usually hard and dense, with low watersolubility. it is commonly used in making fish feed. The machine can adjust thesize and shape of the feed, and control whether it floats or sinks. This helps meetthe eating habits of different aquatic animals like fish, shrimp, and crabs. it canalso be used to make feed for many land animals, The machine settings can bechanged based on what kind of animal feed you need.

We have developed a solution for pet feed production according to the latest standards, researched and developed various pet feed production equipment to meet the constantly increasing production needs of pet food and optimize your production costs.

Customized

Customized

Customized

Customized

Customized

Customized

Customized

Customized

VIDRO INTRODUCTION

Focusing on the field of aquatic feed production to meet the diverse needs of the rapid development of the aquaculture industry.

Ruiqi Aquatic Feed Production Equipment helps you achieve success in the feed production field.

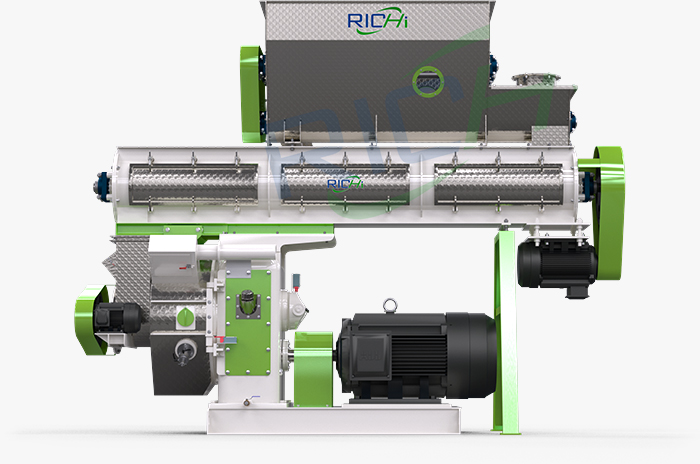

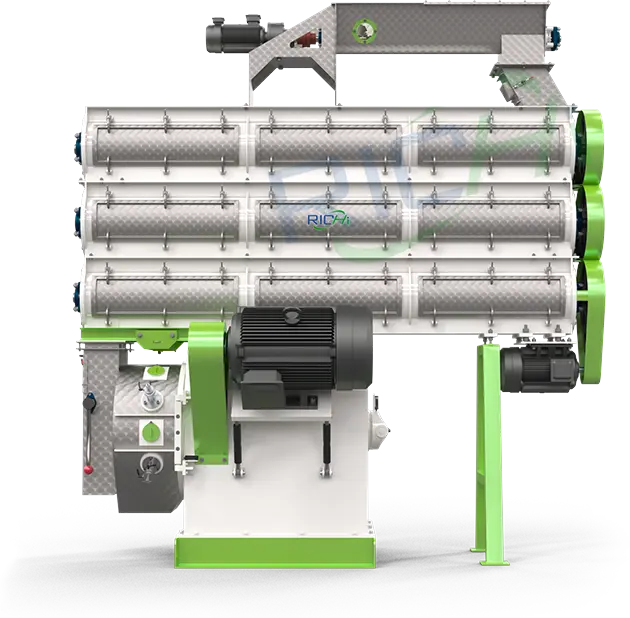

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Cleaning And Crushing System

The above is an introduction to the general principles and characteristics of hammer mills.

Why Choose RICHI Machinery

Choosing RICHI Machinery means you’ll receive not only high – quality equipment but also one – stop solutions and comprehensive service support. Here are some key reasons to choose us

Choosing RICHI Machinery means you’ll receive not only high – quality equipment but also one – stop solutions and comprehensive service support. Here are some key reasons to choose us

30 Years Of IndustryExperience

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

30 Years Of IndustryExperience

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

30 Years Of IndustryExperience

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

VIDRO INTRODUCTION

These are some of the complete chicken feed pellet projects successfully delivered by RiCHl Machinery.All of the projects adopt advanced feed pellet equipment, designed by our RlCHl company to meet customers’demands

16 T/H Livestock Feed Pellet Mill Italy

Our feed pellet machine meets the demands of almost every conceivable every application

More →

16 T/H Livestock Feed Pellet Mill Italy

Our feed pellet machine meets the demands of almost every conceivable every application

More →

16 T/H Livestock Feed Pellet Mill Italy

Our feed pellet machine meets the demands of almost every conceivable every application

More →

RICHI’s Footprints

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutionsUnderstand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

1-2 T/H FISH FEED PROCESSING LINE PROJECT

systems with an hourly outputAt present. wen 80 countres crounc the woric,cna naveof +2 tons in more thancountries include major aquaculture countries such as India.USA, Brazil, Ecuador. Vietnam,Bangladesh, Egypt, Chile and Philippines.

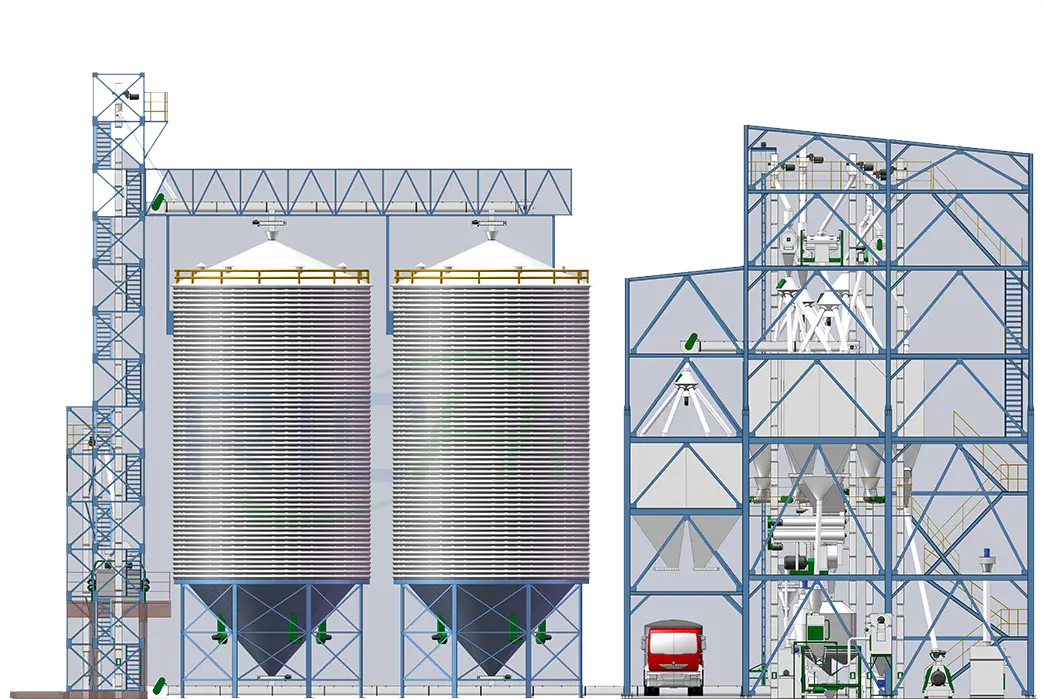

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

01

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

02

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

03

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

04

Silo System

Feed type: Floating fish, shrimp, livestock and poultry

Silos are mainly used to store raw materialsin fish feed processing lines for easymanagementand use. For large-scale fishfeed mil, silos are obviously very necessanlf it is a small-scale fishfeed production lineyou can decide whether to confiqure silos oconfigure small-scale silosvolbudget.We can provide customized silaoeoreViCes

- Cost : approximately $330,000

- Production; cycle : 60 days

- Delivery time : by sea, 40 days

- Installation period : 90 days

- Number of employees : 12

- Working system : single shift, 8 hours per shift, 250 days per year

- Project voltage : 380v/50Hz/3P

05

RICHI VIDEO

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions

DISCOVER OUR PRODUCTS

Specifically, poultry feed pellet making machine can be used for making laying hen feed, broiler feed, duck feed, turkey feed, goose feed, pigeon feed

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.