FACTORY STRENGTH DISPLAY

because this revision plan only contains the host machine, so the three major productplus anauxiliary molds. so the three major productplus an because this revision plan only containsthe host machine

FEED PELLET

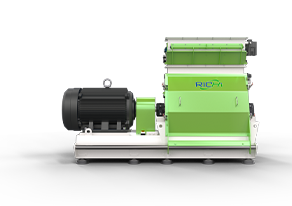

FEED PELLET MAKING MACHINE

RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed

RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed production solutions make the difference for the feed RICHI tailor-made feed production solutions

+86 13673697927

Features OfThe Feed Pellet Production Line

- Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

- Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

- Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

- Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

- Simple operation, can reduce the labor consumption. The small producion line only needs 12 persons. Even the large ducion ine needs 5-10 persons

- lt is suitable for the feed production plant of different scales, farms and individuals who raise animals.

Poultry feed machine projects

The supported adjustment sites are as follows. You can choose to use the “multi-language site” template that comes with the

Wear parts life

Special or patented technology improves the life of wear parts, shortens the replacement time of wear parts, and ensures that the economic interests of customers are not damaged.

Wear parts life

Special or patented technology improves the life of wear parts, shortens the replacement time of wear parts, and ensures that the economic interests of customers are not damaged.

Wear parts life

Special or patented technology improves the life of wear parts, shortens the replacement time of wear parts, and ensures that the economic interests of customers are not damaged.

Wear parts life

Special or patented technology improves the life of wear parts, shortens the replacement time of wear parts, and ensures that the economic interests of customers are not damaged.

Application OfFeed Pellet Production Line

- Can process various raw materials into feed pellets.

- Can process various raw materials into feed pellets.

- Widely used in the large scale and medium scale feeding production plant,animal farms and individuals who raise animals.

- Widely used in the large scale and medium scale feeding production plant,animal farms and individuals who raise animals.

- Can process various raw materials into feed pellets.

Feed Pellet Production Line Working Process For Small Capacity

‘ezoisno ol sn oluo eal indinohup jo alu uononpold p pling ol peau eu ehpy noh lflul buxpw! elad peelipwlup uh7! p s11 ‘eouelelel noh jol ubiseo uooam pu alu uogpnpold pee, indno jolso oapin pup poyo moy au s fumoloy aul “spuup sno!pn oj agqpins au uopnpold aled pal, aadw0o p joubsep au! apold uno am ‘srawoisryo speau oypadseu . 6uplooy weshs bul6oyond puo ‘waishs buoo waisils buzegad “weaishs bukw ‘sulegshs buusnl5 pyepu mp!sapnpu! Aupu a uopnpold gaed pee! ul

01

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

02

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

03

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

04

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

05

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat,

PRODUCTION LINE DISPIAY

RICHI tailor-made feed production solutions make the difference for the feed

13-18T

This section mainly expresses that the pro This section

13-18T

This section mainly expresses that the pro This section

13-18T

This section mainly expresses that the pro This section

13-18T

This section mainly expresses that the pro This section

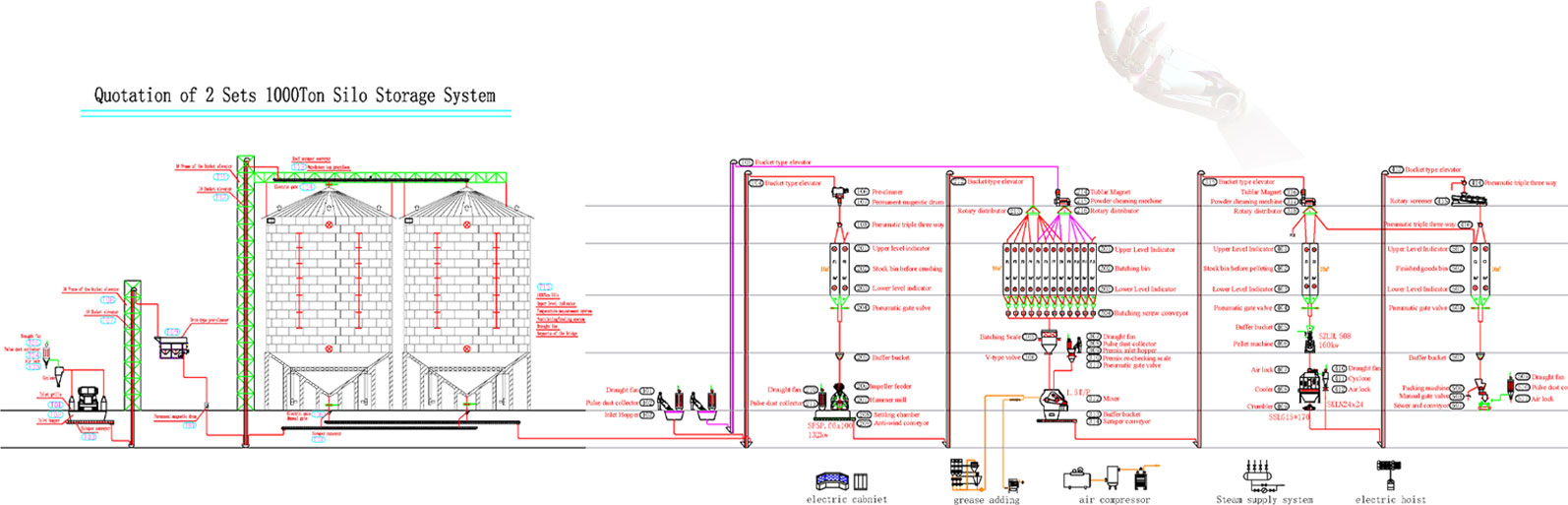

Feed Pellet Production Line Working Process For Large Capacity

We can design fed peletlines of various production capacity,the folowing is the fow chat and video of large output fed production line that we can design for your relerenc. t i 8-12t/h animal feed production line, if you have any pelletizing requirements, welcome to contact us to provide you with pelletizing solutions.

1

Cleaning&Crushing System

The raw materials are put into the feeding hopper, then transported into the cleaning system vertically up by the bucketelevator. After a preliminary cleaning screen of a drum type precleaner, a permanent magnet cylinder, and then dis tributed by rotary distributor to different silos to be distributed, Then the raw materials enter the water-drop hammer mifor crushing, and the crushed raw materials are conveyed by bucket lift to the bin to be mixed.

1

Cleaning&Crushing System

“o]e^ala jayong au g sulg bulzallad-a」d ay, o juas aje au! ‘paxlu s! eualeu au! 19y6ulxiuu jo abeis ply, ay! weis o, weis’s buippe aseas6 ay! ybnosy, laxiu ay oju! pey s! aseai6 ay! ‘Keul buIx!uu SIE-wajeuu lelus jo abeis puooas ay, jeis o1iaddou buipaay sieualew ljeus au, olu! ind si xuasd au, uay, .6uixu jeiso1 laxlul au, oqul sleuaiew abuel au! s! abeis isuly au :sabeis aaly, ou! papilp s! sjeuaieuu jo yoeq yoee jo bulx!uauI “9E uey! ssa| s! 10e bulyoleG leIeA0 ‘6ulyojeq aieinooe analyoe ol sainduoo Kq palonuoo si ajeos fuiyoieg

3

Cleaning&Crushing System

The materials are transferred to the tempering conditioner through the variable frequency speed feeder. The variablefrequency impeller feeder can control the feeding speed, so that the feed pellet maker can work under ideal conditionsas much as possible.

The mixed bowder materials contact and fuse with steam in the conditioner. After the materials are modulated to acertain temiperature and moisture, enter the ring die of the pelletizer. Under the strongly extrusion between the ring dieand the press roller, the pellets are formed and then cut into the desired length by the cutter.

The feed cqoling machine is placed under the feed pellet machine, saving both floor space and the use of conveyingequipment and storage bins. Cooling the temperature of the feed pellets to room temperature can avoid the phenomenon of sudden cooling caused by direct contact between cold air and hot material, and thus prevent the surface crack

ing of pellets

4

Cleaning&Crushing System

The svstem can pack the feed pelets into bags fully automatically, which makes it more convenient for stdrage and transportation.

RlCHl packaging machine has an independent electric control cabinet, which can set the packaging weightlon the program for automatic packaging.

Feed Pellet Production Line Working Process For Small Capacity

‘ezoisno ol sn oluo eal indinohup jo alu uononpold p pling ol peau eu ehpy noh lflul buxpw! elad peelipwlup uh7! p s11 ‘eouelelel noh jol ubiseo uooam pu alu uogpnpold pee, indno jolso oapin pup poyo moy au s fumoloy aul “spuup sno!pn oj agqpins au uopnpold aled pal, aadw0o p joubsep au! apold uno am ‘srawoisryo speau oypadseu . 6uplooy weshs bul6oyond puo ‘waishs buoo waisils buzegad “weaishs bukw ‘sulegshs buusnl5 pyepu mp!sapnpu! Aupu a uopnpold gaed pee! ul

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

Drum Type Precleaner

RICHl Machinery Drum type precleaner is widely used in theraw material receiving part of feed pellet plant and other industries. Mainly used to remove large impurities such asrice straw, straw, hemp rope, corn cobs and etc to protectthe feed pellet processing equipment from failure ordamage.

SERVICE PROCESS

RICHI tailor-made feed production solutions make the difference for the feed

Projects Cases Of Chicken Feed Pellet Machine For Sale

These are some of the complete chicken feed pellet projects successfully delivered by RiCHl Machinery.All of the projects adopt advanced feed pellet equipment, designed by our RlCHl company to meet customers’demands

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

16 T/H Livestock Feed Pellet Mill Italy

- Country: China

- Date: June 2016

- Total Power: 805KW

- Workshop size about this project: 20000m?

RICHI MACHINERY

How To Set Up A Poultry Feed Mill?

Poultry feed processing is never limited to one poultry feed pelleting machine, it is only one of the core equipment of a poultry feed factory, and many equipments are needed to work together to form a complete poultry feed processing process. Well, you need Richi Machinery.

Understanding the needs of each customer is awe of feed processors. In the field of poultry feed processing, Richi Machinery is committed to creating world-class feed mill solutions. Our ultimate goal is to reduce the cost of use of customer equipment, improve the efficiency of equipment use, and help customer industries take root and deepen their cultivation.

100+

Years Experience

100+

Years Experience

100+

Years Experience

100+

Years Experience

Frequently Asked Questions

If you have any other questions, please email us.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

The above is an introduction to the general principles and ?

+

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.