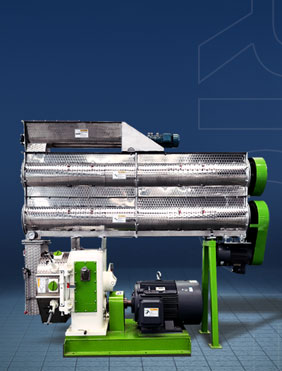

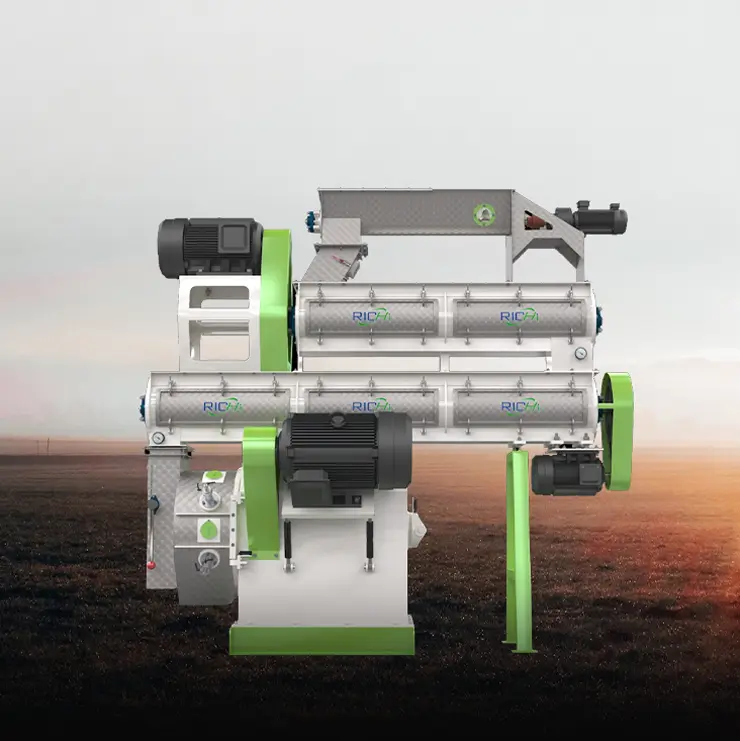

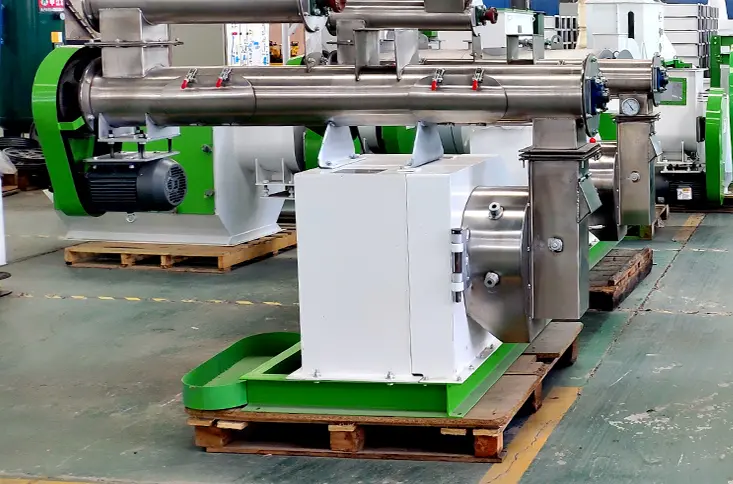

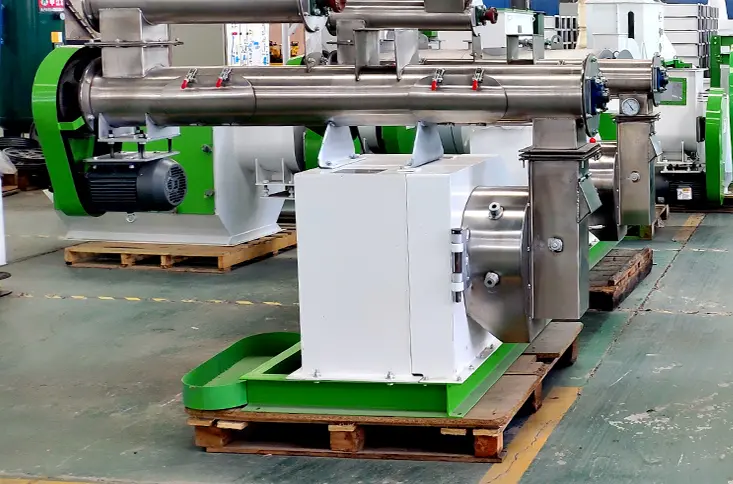

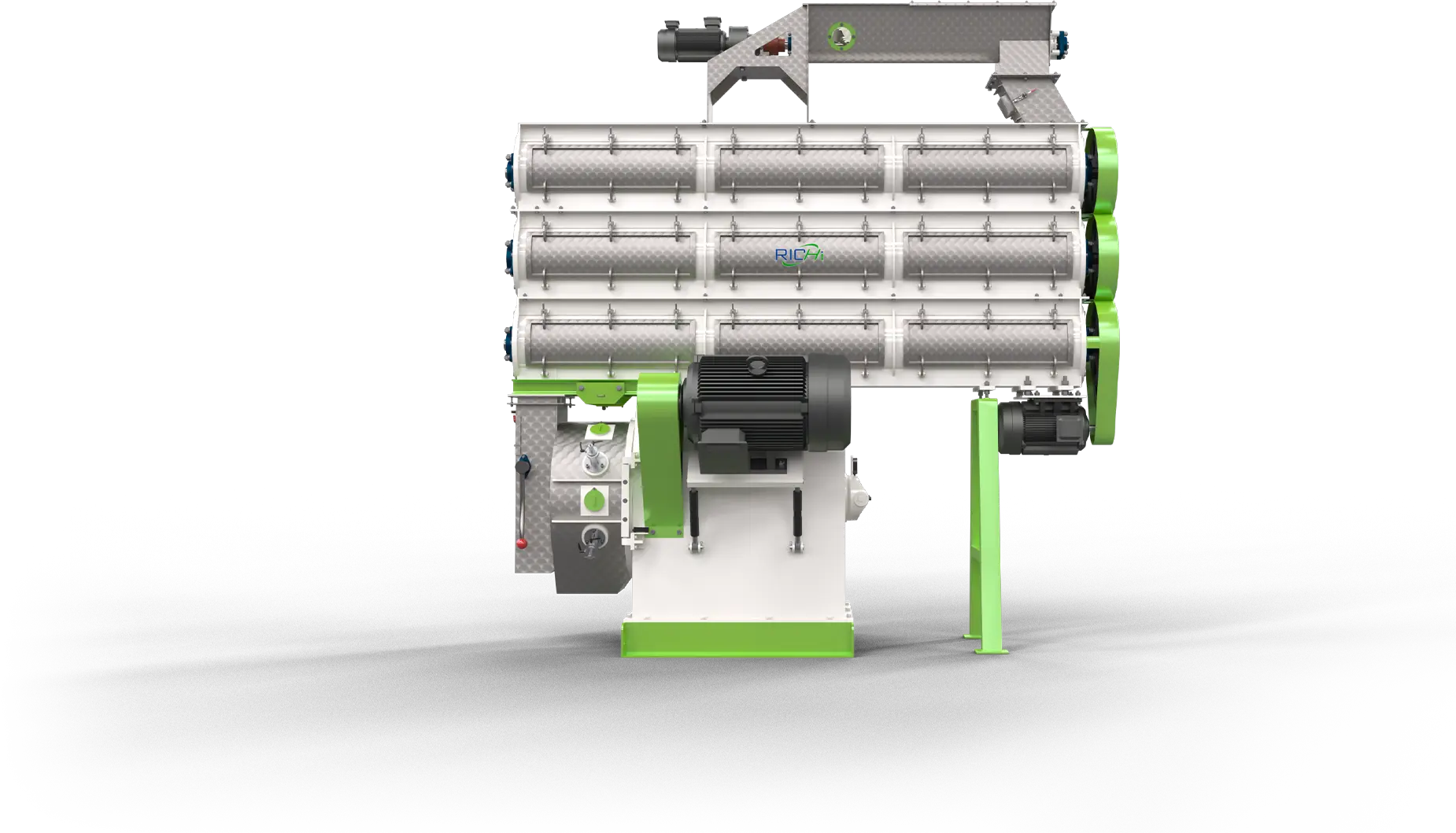

Feed Pellet Machine

High efficiency, Stable and classical gear driving, non-slipping, can really ensure the productionoutput Low noise, optimized ring die, maximum output.

ADVANTAGES OF POULTRY FEED PELLET MAKING MACHINE

RICHI tailor-made feed production solutions make the difference for the feed

High Output And Low Energy Consumption

Poultry Feed Pellet Machine ring die

Ring die working area: 319342-1243756mm² Ring die size: 535190-1070370mm high quality bearings, optimized bearing configuration, stable operation of poultry pellet making machine. stable operation of poultry pellet making machine.

Poultry Feed Pellet Machine ring die

Ring die working area: 319342-1243756mm² Ring die size: 535190-1070370mm high quality bearings, optimized bearing configuration, stable operation of poultry pellet making machine. stable operation of poultry pellet making machine.

Poultry Feed Pellet Machine ring die

Ring die working area: 319342-1243756mm² Ring die size: 535190-1070370mm high quality bearings, optimized bearing configuration, stable operation of poultry pellet making machine. stable operation of poultry pellet making machine.

Poultry Feed Pellet Machine Price

Customizable Plan: Richi Machinery can customize the poultry feed pellet making machine according to the actual needs of customers,

FEED PELLET

FEED PELLET

FEED PELLET

FEED PELLET

Poultry Feed Pellet Machine Price

Customizable Plan: Richi Machinery can customize the poultry feed pellet making machine according to the actual needs of customers,

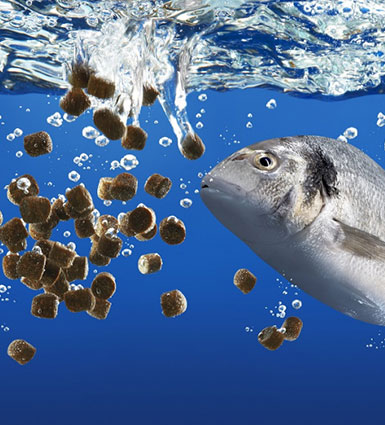

Feed Conversion Rate

Poultry pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily

Feed Conversion Rate

Poultry pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily

Feed Conversion Rate

Poultry pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily

Feed Conversion Rate

Poultry pellet feed can promote the increase of poultry weight by 4.59% to 11.76%; it can improve the feed conversion rate and easily

Shrimp feed pellet machine parameters

| Title | Title | Title |

| SZLH250 | 1~2 | 22 |

| SZLH250 | 1~2 | 37 |

| SZLH250 | 1~2 | 37 |

Why Choose RICHI Machinery

Choosing RICHI Machinery means you’ll receive not only high – quality equipment but also one – stop solutions and comprehensive service support. Here are some key reasons to choose us:

30 Years Of IndustryExperience

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Complete After-Sales Service

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Built Around Your Needs

Since its establishment in1995, RICHl Machinery hasamassed 30 years of richexperience in the design,production, and R & D ofanimal feed processing_plantWith our profound technicalaccumulation and globaldevelopment, we can provideour customers with reliableequipment and solutions.

Production Process OfAnimal Feed Processing Machie In Ethiopia

The animal feed pellet machine is the core equipment of the pelleting section of theThis equipment plays a vitaMvaceecnn nrole in the production of high-quality livestock and poultry feed pellets

In order to convert raw materials into finished animal feed pellets, the production line usualy includes processes such as crushing,is crucial, and the animal feed pellemixing.and packagimachine is the main equipment used. The following are the detailed production steps of the animal feed production line

Brief Introduction

Animal feed processing machine in Ethiopia integrates crushing, mixing, pelleting, cooling and packaging into a sireamlined and efficient system..Whether it is for poultry, cattle,sheep or other livestock, the production process ensures balancednutriion,stable quality and high yeld. With automalion and precise control, RICHls fed soltions are helping thiopian feed mils modernize and expand fture operations.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

SERVICE PROCESS

RICHI tailor-made feed production solutions make the difference for the feed

Production Process OfAnimal Feed Processing Machie In Ethiopia

The animal feed pellet machine is the core equipment of the pelleting section of theThis equipment plays a vitaMvaceecnn nrole in the production of high-quality livestock and poultry feed pellets

In order to convert raw materials into finished animal feed pellets, the production line usualy includes processes such as crushing,is crucial, and the animal feed pellemixing.and packagimachine is the main equipment used. The following are the detailed production steps of the animal feed production line

Brief Introduction

Animal feed processing machine in Ethiopia integrates crushing, mixing, pelleting, cooling and packaging into a sireamlined and efficient system..Whether it is for poultry, cattle,sheep or other livestock, the production process ensures balancednutriion,stable quality and high yeld. With automalion and precise control, RICHls fed soltions are helping thiopian feed mils modernize and expand fture operations.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Cleaning And Crushing System

the raw materials are irst ed into he tet hopper and veaicayiedtohe deaningsecion bya bucket alewao. he raw maienas are irs preceaned oya dnm scren, and thean a pemanent magneic dinum suseo to remove iron impurities. After the raw materials are fed into a separate storage silo, they are finely ground by a hammer mill and then transported to the mixing silo for the next stage of processing.

Poultry Feed Pellet Machine Price

The supported adjustment sites are as follows. You can choose to use the “multi-language site” template that comes with the

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

The production scale of the poultry

If the scale of feed production is expanded, it is necessary to increase the number of poultry feed pellet making machine or poultry feed production lines, and the total investment price will basically increase proportionally.

How To Choose The Right Animal Feed Processing Machine In Ethiopia

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

What Kind Of Livestock Are You Raising?

+

The ype of animalyou raise detemmines the reguired pellet siz. Poury, cale, sheep, goats, and fish alreure pelelis of diferent diameiers for opimal nutrion and digestibilit.

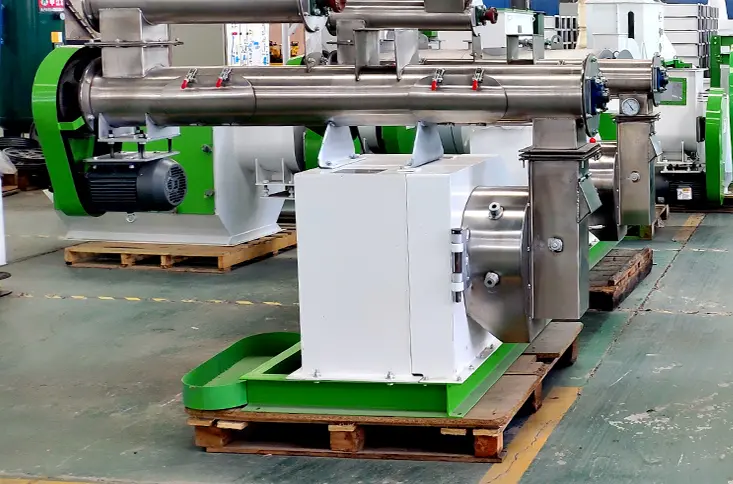

RICHI MACHINERY

Product Display

How to make poultry feed machine? If the meaning of this question is really to process poultry feed equipment by yourself, then I have to say that the poultry feed machine is a very high-tech equipment