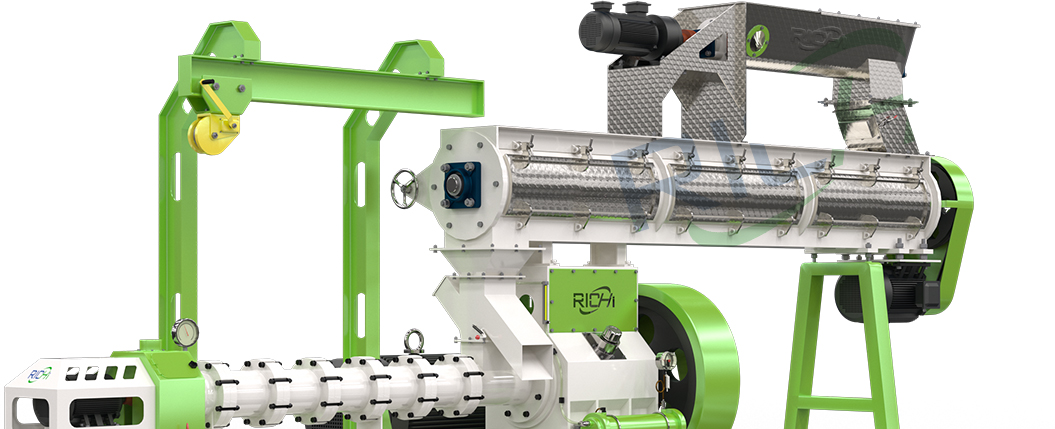

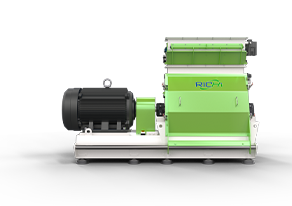

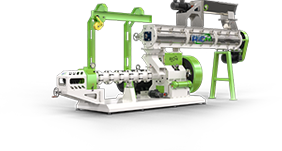

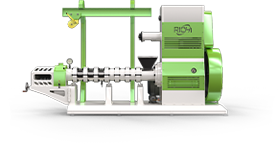

FLOATING FISH FEED LINE

Floating fish feed machine manufacturer The latest extrusion technology enables you to produce the best floating aquafeed

Product Introduction

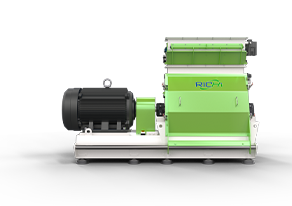

Dry type fish feed extruder is a commonly used machine for producing floating or sinking equipment is suitable foismall to medium-sized fish farms or mini feed processing plants,

‘slew!ue nenbe sauio pue’sqes ‘dw!цs ‘us!} so」 paa↓ joauiul pasn 从apIM SI pue

lt has a unique design that allows precise control over the density of the final feed, making it possible to produceeither floating or sinking feed as needed, At the same time, operators can aciust the process parameters to controlthe texture of the feed, such as its ability to absorb oil during later coating processes.

As a professional feed machinery manufacturer, RiCHl offers dry fish feed extruders mainly for producing aquatic feed pellets with diameters ranging from 0.5 to 8 mm in various shapes and lengths. They can also be used to produce pet or poultry feed pellets up to 50 mm in diameter.

Suitable Animals

The feed made by dry extruders is usually hard and dense, with low watersolubility. it is commonly used in making fish feed. The machine can adjust thesize and shape of the feed, and control whether it floats or sinks. This helps meetthe eating habits of different aquatic animals like fish, shrimp, and crabs. it canalso be used to make feed for many land animals, The machine settings can bechanged based on what kind of animal feed you need.

Featured Program

We have developed a solution for pet feed production according to the latest standards, researched and developed various pet feed production equipment to meet the constantly increasing production needs of pet food and optimize your production costs.

Customized

Customized

Customized

Customized

Customized

Customized

Customized

Customized

Technical features

Single-screw dry fish feed extruder is simple in structure, ffordable, and very stable to use. This machine has been developed for manyyears with mature technology, making it reliable and problem-free. For over 40 years, it has been the main equipment for producingextruded fish feeds, especially suitable for low-protein feeds for adult fish like tilapia, grass carp, and carp.

In the production of ordinary feeds, such as those used formixed pond fish, this machine offers significant advantages.Raw materials do not need to be ground too finely; most canpass through a 30 to 50 mesh sieve, This eliminates the needfor expensive grinding equipment, saving costs and makingproduction faster and easier.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

01

Casting Manufacturing

The active transmission box is a castingwith high hardness, large load-bearing capacityand long service life.

How the Dry Type Fish Feed Extruder Works

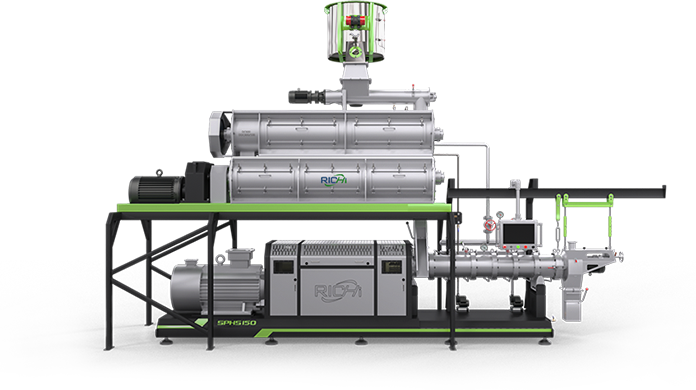

RiCHl dry type fish feed extruder is mainly made up of a feeding device, screw,pressure chamber, shaping die, cutter, driving system, and control system.

Here’s how the dry single-screwfish feed extruder works.

First , the mixed raw materials are put into the machine through the feeding port. As the screwr otates,it pushes the materlals into the machine, The materlals are pressed:and rubbed between the screw and the barrel, which causes heat (no external heating is needed). Thisheat makes the starch gelatinize and the protein denature, turning the powder into a sticky mass.

First , the mixed raw materials are put into the machine through the feeding port. As the screwr otates,it pushes the materlals into the machine, The materlals are pressed:and rubbed between the screw and the barrel, which causes heat (no external heating is needed). Thisheat makes the starch gelatinize and the protein denature, turning the powder into a sticky mass .

When the pelets come out ofthe die,the pressure drops quickly. The moisture insideturms into steam and expands,making the pelets light and aigy.Depending on how much they expandthe pellets can either float on water or sink to the bottom. This meets the different feeding habits of various fish.

Duing the whole proces, the machine uses the mechanical enrgy from the screw rotationto create hea, sono extra steamis needed.Both the screw and barrel are made fromwearresistant,high temperature aloy stel The machine has a compact design and is easyto operate, making it an economical and practicalsoltion for fsh fed production.

Technical Specifications of the Dry Type Fish Feed Extruder

| Model | SZLH250 | SZLH250 | SZLH250 | SZLH250 | SZLH250 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 2-12 | ||||

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

| Main Motor Power(kw) | 22 | 22 | 22 | 22 | 22 |

We are a professional manufacturer of fish feed extruders and offer a variety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder. lf you need a machine with

a diferent capacity, please let us know your requirements, and we will customize a solution for you.

Benefits Of Using A Dry

Fish Feed Extruder To Produce Pelleted Feed

We are a professilonal manufacturer of fish feed extruders and offer a varlety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder, if you need a machine witha different capacity, please let us know your requlrements, and we will customize a solution for you.

RICHI VIDEO

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions

Video Showcase

The above is an introduction to the general principles and characteristics of hammer mills.

MORE CASES

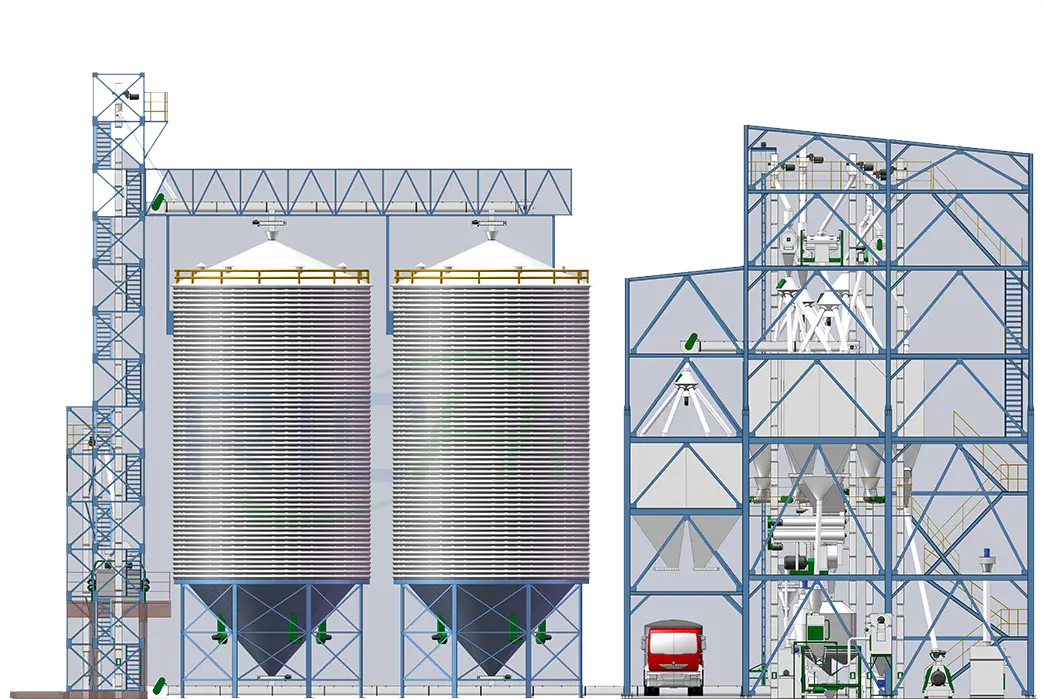

We can design feed pellet lines of various production capacity, the following is the flow chart and video of large output feed production line that we can design for your reference. It is a 8-12t/h animal feed production line, if you have any pelletizing requirements, welcome to contact us to provide you with pelletizing solutions.

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

0.8-4 t/h straw pelletmachine fo!sale South Africa

We can help you with the entire process. Fromraw material handling and crushingto control siftingpelleting and cooling, our experts can tailorWe can help you with the entire process. From rawmaterial handling and crushingto control

Customer Reviews

since 1995, RicHl Machinery has served thousands of customers and received countiess high praise.We are commilted to bringing our customers

the best products and the most perfect experience.

Robert Rosario

RlCHl professional products, sincereservice convinced us. We choseRiCH,.they perfectly solved ourproblem of producing wood pellets.They help usbuild a wood pelletplant, from unique design, themanufacture of pelletizing equipment, we are very satisfied,

Tanzania

GOOD SERVICE

Robert Rosario

RlCHl professional products, sincereservice convinced us. We choseRiCH,.they perfectly solved ourproblem of producing wood pellets.They help usbuild a wood pelletplant, from unique design, themanufacture of pelletizing equipment, we are very satisfied,

Tanzania

GOOD SERVICE

RICHI’s Footprints

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutionsUnderstand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Mixing

03

During mixing, all the ingredients are measured accurately based on the formula and then mixed well in a mixer. This makes sure that every feed pellet has the same nutrition.

Feed Pellet Production Line Working Process For Small Capacity

‘ezoisno ol sn oluo eal indinohup jo alu uononpold p pling ol peau eu ehpy noh lflul buxpw! elad peelipwlup uh7! p s11 ‘eouelelel noh jol ubiseo uooam pu alu uogpnpold pee, indno jolso oapin pup poyo moy au s fumoloy aul “spuup sno!pn oj agqpins au uopnpold aled pal, aadw0o p joubsep au! apold uno am ‘srawoisryo speau oypadseu . 6uplooy weshs bul6oyond puo ‘waishs buoo waisils buzegad “weaishs bukw ‘sulegshs buusnl5 pyepu mp!sapnpu! Aupu a uopnpold gaed pee! ul

01

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

02

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

03

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

04

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

05

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat,

06

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

07

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

08

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

09

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat, they needcrushing into powered materi-als. Then put them in to the next section.

10

Crushing system

The first step of the line is tocrush the raw materials. The materials include the corn, soy-bean meal, wheat,

Animal Feed Pellet Production Line

Ne can help you estabish various animal feed processing plants such as aqua feed plant, cate feed pellet production line, pig feed plant and other feed pellet production line.

Other Related Feed Production Equipment

RcHlMachinenv has been dedicaiedto extruson tectinodlovfor neary 30 ears, e are commted to proiding dlobal.cusomeswith eficientandrelablefish fed exruders and completesoltions.we focaus or the research and innovation ofeed production equipment, continuouslyimproving performance to help customers increase production eficieny and product qualty.

Wet Type Fish Feed Extruder

We start by understanding your production

needs and goals.

Wet Type Fish Feed Extruder

We start by understanding your production

needs and goals.

Wet Type Fish Feed Extruder

We start by understanding your production

needs and goals.

Twin-Screw Fish Feed Extruder

We start by understanding your production

needs and goals,

Frequently Asked Questions

We are a professional manufacturer of fish feed extruders and offer a variety of models for you to choose from.The table below shows the parameters of some common models of dry type fish feed extruder. if you need a machine with a different capacity, please let us know your requirements, and we will customize a solution for you.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.

–

The above is an introduction to the general principles and ?

The organic fertilizer granules making machine has a fast granulation speed, which can improve productior efficiency and meet the needs of organic fertilizer processing plants, farms and farms of different sizes.

Founded in 1995,Richi Machinery has been developing steadlly and steadily in the field of pellet processing. t is mainly engaged in the R&D andmanufacturing of pelet plant equipment founded in 1995, ichi Machinary has bean developing steadily cind steadilyin the feld of pelet processing.It is mainly engaged in the R&D and manufacturing of pellet plant equipment founded in 1995, Richi Machinary has been developing steadlily and

steadily in the field of pellet processing.